2

GENERAL NOTES

1.

GENERAL

The treatment system is complete with all needed equipment as shown on the drawings and specified

herein. The following items of equipment are provided by BioMicrobics, Inc., with purchase of the

system: (a) the FAST system sub-assembly, (b) foot top and foot bottom, (c) blower assembly, and (d)

blower controls and alarms. All other items needed for installation and operation are not included.

The contractor will install the FAST® treatment system as manufactured by BioMicrobics, Inc. The

contractor will ensure the proper fabrication of the tank, coordinate between the tank suppliers and

FAST® system suppliers, arrange delivery to the job site, and oversee the installation of the FAST® unit.

The tank must provide adequate pump-out access and must conform to local, state, and all other

applicable codes. The tank must also be level within ±1/2 in [12 mm].

2.

MEDIA

The FAST media is made of rigid PVC, polyethylene, or polypropylene, and it is supported by the

polyethylene insert. The media will be fixed in position and contain no moving or wearing parts, and it

will not corrode. The media has been designed (and will be installed) to ensure that sloughed solids

descend through the media to the bottom of the septic tank for easy cleanout.

3.

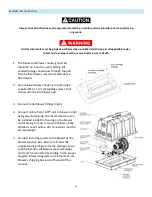

REMOTE MOUNTED BLOWER

The blower must be set in a dry, stable place, and its elevation must be higher than the normal flood

level. A two-piece, rectangular housing is included with the unit. The discharge air line from the blower

to the FAST system is not included and must be provided and installed by the contractor.

4.

ELECTRICAL

The electrical source should be within 150 ft [45 m] of the blower; consult local codes for longer wiring

distances. Wiring distances must prevent significant voltage loss. All wiring must conform to all

applicable codes (IEC, NEC, etc.). Actual power consumption varies with site conditions. All conduit and

wiring must be supplied by the contractor.

5.

CONTROLS

The control panel, which provides power to the blower, comes with an alarm system consisting of a

visual and audible alarm that will signal blower circuit failure and high motor load The control panel is

equipped with an SFR® (Sequencing Fixed Reactor) timed control feature. A manual silence button is

included.

6. INSTALLATION AND OPERATING INSTRUCTIONS

Written instructions for proper installation, use, and service of the FAST® system (manuals) are

included with the product and are available online at the BioMicrobics website. Installation of the

FAST® system must be carried out in accordance with the written instructions provided in the

Installation Manual. Moreover, all work related to the installation must be done in accordance with

local codes and regulations.

Summary of Contents for HighStrengthFAST 4.5

Page 2: ...1...

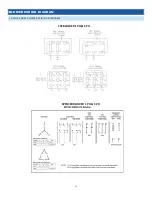

Page 15: ...12 FUJI BLOWER 1 PH FUJI BLOWER 3 PH...

Page 16: ...13 GAST BLOWER 1 PH...

Page 19: ...16 3PH 208V 240V 1PH 208V 240V 3PH 460V...

Page 20: ...17 CONTROL PANEL SCHEMATICS...

Page 21: ...18...

Page 22: ...19...

Page 23: ...20...