22

LIMITED WARRANTY

BioMicrobics, Inc. warrants the following systems

RetroFAST® 0.15, 0.25, 0.375

Residential MicroFAST® 0.5, 0.625, 0.75, 0.9, and 1.5

BioBarriers 0.5, 1.0, 1.5, 0.5-N, 1.0-N, and 1.5-N

STAAR® 0.5, 0.75, 1.0, 1.2, and 1.5

against defects in materials and workmanship, for a period of two years after installation or 30 months from

date of shipment. For all other systems and spare parts, BioMicrobics Inc. warrants against defects in materials

and workmanship for a period of one year after installation, or eighteen months from date of shipment,

whichever occurs first, subject to the following terms and conditions.

TERMS AND CONDITIONS

Note: For this warranty to be effective, BioMicrobics must have received the product

registration for the system.

During the warranty period, if any part is defective or fails to perform as specified when operating at design

conditions, and if the equipment has been installed and is being operated and maintained in accordance with

the written instructions that BioMicrobics, Inc. has provided, BioMicrobics, Inc. will repair or replace at its

discretion such defective parts free of charge. Defective parts must be returned by owner to BioMicrobics,

Inc.’s factory postage paid, if so requested. The cost of labor and all other expenses resulting from

replacement of the defective parts and from installation of parts furnished under this warranty shall be borne

by the owner. This warranty does not cover general system misuse, aerator components that have been

damaged by flooding or any components that have been disassembled by unauthorized persons, improperly

installed or damaged due to altered or improper wiring or overload protection. This warranty applies only to

the treatment system and does not include any of the structure wiring, plumbing, drainage, septic tank or

disposal system. BioMicrobics, Inc. reserves the right to revise, change or modify the construction and/or

design of the BioMicrobics system, or any component part or parts thereof, without incurring any obligation to

make such changes or modifications in present equipment. BioMicrobics, Inc. is not responsible for

consequential or incidental damages of any nature resulting from such things as, but not limited to, defect in

design, material, or workmanship, or delays in delivery, replacements or repairs.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED. BIOMICROBICS, INC. SPECIFICALLY DISCLAIMS ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NO REPRESENTATIVE OR PERSON IS

AUTHORIZED TO GIVE ANY OTHER WARRANTY OR TO ASSUME FOR BIOMICROBICS, INC. ANY OTHER LIABILITY IN CONNECTION WITH

THE SALE OF ITS PRODUCTS.

Summary of Contents for HighStrengthFAST 4.5

Page 2: ...1...

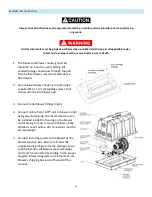

Page 15: ...12 FUJI BLOWER 1 PH FUJI BLOWER 3 PH...

Page 16: ...13 GAST BLOWER 1 PH...

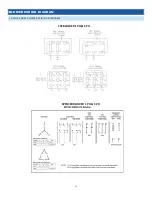

Page 19: ...16 3PH 208V 240V 1PH 208V 240V 3PH 460V...

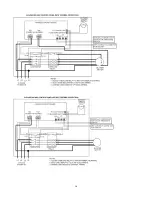

Page 20: ...17 CONTROL PANEL SCHEMATICS...

Page 21: ...18...

Page 22: ...19...

Page 23: ...20...