Part No. 400988 Form No. F010496B

Page 3 of 8

For your safety and the safety of others, these directions should be followed:

Use of Ear Protection is recommended while

operating this machine.

Do not operate this machine without first reading

owner's manual and engine manufacturer's manual.

Use of Eye and breathing protection is recom-

mended when using this machine, especially in

dry and dusty conditions.

GENERAL SAFETY

9

9

9

9

9

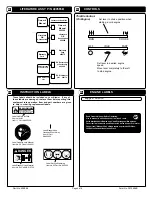

PACKING CHECKLIST

11

11

11

11

11

·DO NOT place hands or feet inside air intake opening, near

exhaust outlet or near any moving parts.

·DO NOT start engine without deflector attached to exhaust

outlet.

PUT OIL IN ENGINE BEFORE STARTING

Read all safety and operating instructions

before assembling or starting this unit.

10

10

10

10

10

ASSEMBLY

Your Billy Goat is shipped from the factory in one carton,

completely assembled except for the upper handle

assembly.

These items should be included in your carton. If

any of these parts are missing, contact your dealer.

17

Boxing Checklist

Check

Literature Assy

400565B

Per Model

Check

Briggs & Stratton 5

HP

Per Model

P/N MS9249

Multi-Language

Handle Upper

Assembly

400957

Literature

Assy

Engine

Manual

·DO NOT direct exhaust outlet toward any bystanders.

·DO NOT operate this equipment without first inspecting

work area.

·DO NOT operate this equipment during excessive vibration.

·DO NOT start engine without housing front plate attached.

·DO NOT operate this machine on slopes greater than 20%.

·DO NOT blow any hot or burning debris, or any toxic or

explosive material.

·DO NOT allow children to operate this equipment.

1. Install upper handle (Item 28), to preassembled lower handle (item 29),

using two screws (Item 17), and two nut locks, (Item 32). Securely tighten

all fasteners.

2.Connect spark plug wire.

NOTE: Front wheel bracket (Item 27), can be inverted to provide a

0.5” (12.7 mm) height adjustment.

Check

32

29

28