- 20 -

ElECTRoNiC CoNTRol/iGNiTioN P.C.b.

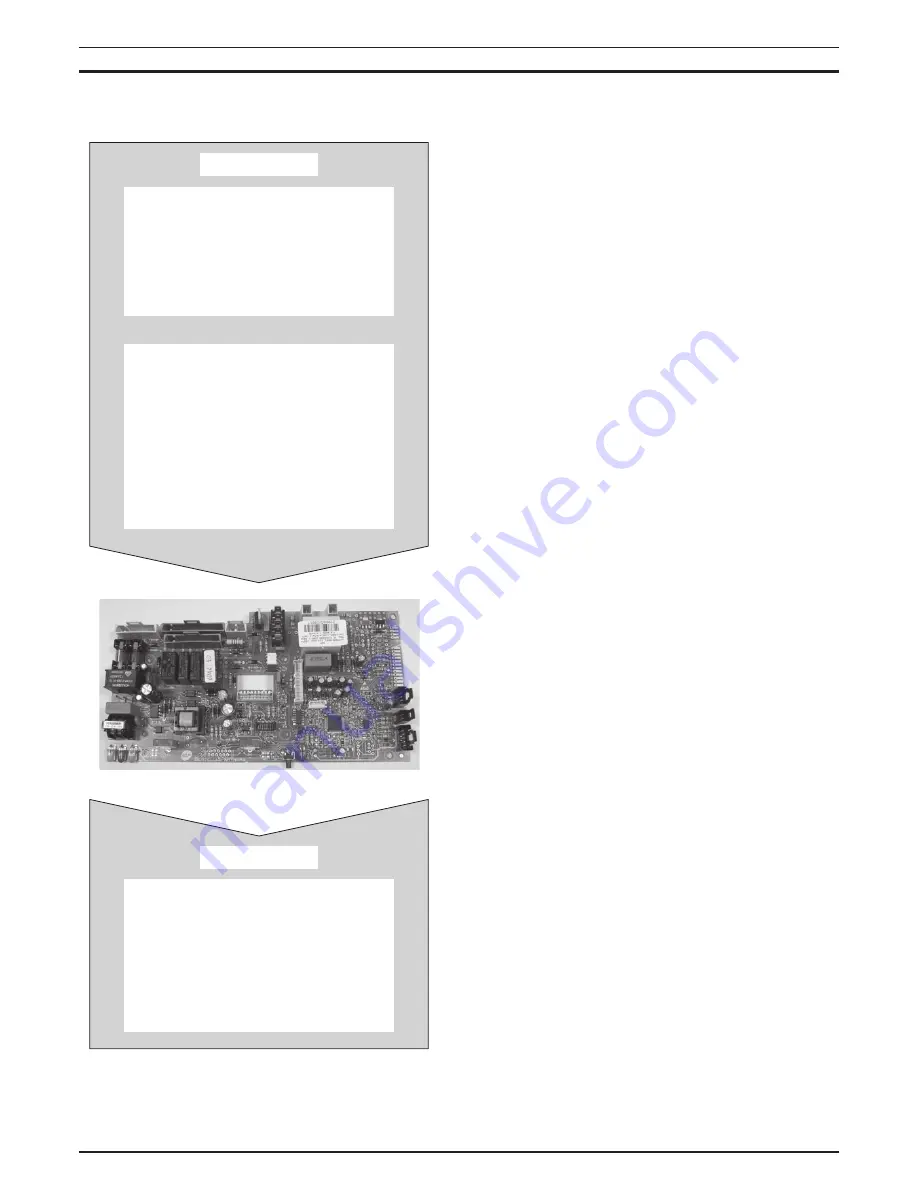

10 ElECTRoNiC CoNTRol/iGNiTioN P.C.b.

10.1 function

figure 10.1

From other boiler devices....

C.h. temperature probe NTC

D.h.w. temperature probe NTC

D.h.w. flow switch

Primary circuit pressure switch

Air pressure sensor

Flue temperature probe NTC

Safety thermostat

Flame detection electrode

Room thermostat (if fitted)

Time switch

On

the

Electronic

control/ignition

p.c.b.......

Function control

C.h. temperature adjustment

D.h.w. temperature adjustment

Boiler reset button

(control panel fascia)

Inlet Information

Pump

Three way diverter valve

On---off operators (gas valve)

Modulation operator (gas valve)

Fan

Ignition electrodes

Appliance operation lights*

Lock---out signal lamp*

*control panel fascia

Outlet command

The fundamental function of the Electronic control/ignition p.c.b.

is that of controlling the boiler in relation to the external needs

(i.e. heating the dwelling or heating the water for d.h.w. use) and

operating in order to keep the temperature of the hydraulic cir-

cuits constant.

This is obviously possible within the useful power and maximum

working temperature limits foreseen.

Generally, the Electronic control/ignition p.c.b. receives inlet

information coming from the boiler (the sensors) or from the

outside (knobs, room thermostat, etc.), processes it and conse-

quently acts with outlet commands on other components of the

boiler (Figure 10.1).

The Electronic control/ignition p.c.b. is also a full sequence igni-

tion device and does a sequence of operations (ignition cycle)

which lead to the ignition of the gas at the burner.

It checks the presence of the flame during the entire period in

which it is activated, supplies the fan and checks its functioning

by means of the signal coming from the air pressure sensor.

The Electronic control/ignition p.c.b. has a safety function and

any incorrect interventions or tampering can result in conditions

of dangerous functioning of the boiler.

The Electronic control/ignition p.c.b. can lock the functioning of

the boiler (lock state) and stop its functioning up to the resetting

intervention. The lock is signalled by the lighting of the lock-out

signal lamp and the device can be reset only by using the boiler

reset button placed on the control panel fascia.

Some components which are connected to the device can acti-

vate the lock state. The causes of a lock state could be:

• The intervention of the safety thermostat (overheat of the pri-

mary circuit).

• The intervention of the flue temperature probe (overheat of the

combustion products).

• A fault on gas supply.

• Faulty ignition (faulty ignition electrodes, their wiring or con-

nection).

• Faulty flame detection (faulty detection electrode, its wiring or

connection).

• Gas injectors blocked.

• Faulty modulation gas valve (faulty on-off operators or not elec-

trically supplied).

• Faulty Electronic control/ignition p.c.b..

Other components like the air pressure sensor can temporar-

ily stop the ignition of the burner but allow its ignition when the

cause of the intervention has stopped.

Figure 10.27 shows the sequence of the operations that are car-

ried out at the start of every ignition cycle and during normal

functioning.

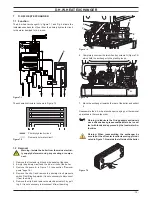

10.2 Selection and adjustment devices

On the Electronic control/ignition p.c.b. several selection, adjust-

ment and protection devices are located (Figure 10.2).

Some of these devices are directly accessible by the user (func-

tion control, temperature adjustment potentiometers etc.) others

are accessible by removing the service panel or the control panel

lid.