Electronic control/ignition p.c.b.

17

Some of these devices are directly accessible by the

user (function control, temperature adjustment poten-

tiometers etc.) others are accessible by removing the

service panel or the control panel lid.

6

7

8

9

10

11

1

2

3

4

5

Fig. 29

1

x1 connector

2

x6 connector

3

x7 connector

4

x4 connector

5

x2 connector

6

Lock---out signal lamp

7

Boiler reset button

8

Function control / C.h. temperature adjustment

9

D.h.w. temperature adjustment

10

Appliance operation lights

11

Fuse 3,15 A F

10.3

Checking the temperature

The Electronic control/ignition p.c.b. makes it possible

to separately adjust the c.h. water flow temperature and

d.h.w. outlet temperature.

The temperature of the water is converted into an elec-

tric signal by means of temperature probes.

The user, setting the desired temperature with the con-

trol panel knobs operates the variable elements (8 and

9 in Fig. 29) of the electronic control p.c.b.

If the power requested is lower than 40% of the maxi-

mum power output then control is achieved by switch-

ing ON the burner at minimum power, then switching

OFF (ON/OFF function). If the power requested is

higher, then the burner is switched ON at maximum

power and will control by modulating to 40% of the

maximum power output.

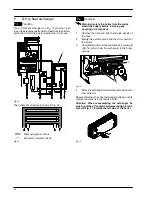

During the c.h. operation (Fig. 30), the signal coming

from the c.h. temperature probe is compared to the sig-

nal given by the control panel through the adjustment

made by the user (knob

). The result of such a

comparison operates the modulation of the gas valve,

consequently changing the useful output of the boiler.

Fig. 30

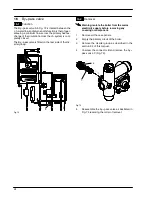

When the boiler functions in d.h.w. (Fig. 31), the signal

coming from the d.h.w. temperature probe is compared

with the signal given by the control panel through the

adjustment made by the user (knob

).