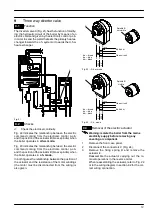

Modulating gas valve

24

B

C

Fig. 48

6

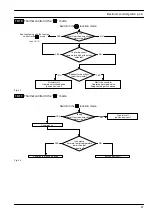

Start the boiler at its maximum power.

Operate the boiler in d.h.w. mode or ensure that

the boiler is not range rated if the test is carried out

in c.h. mode.

7

Rotate the maximum gas pressure adjustment (2

in Fig. 47) until you obtain the required pressure

(by rotating clockwise the pressure increases).

8

Turn the boiler off and disconnect one of the two

connectors (3 in Fig. 47).

9

Start the boiler and rotate the minimum gas pres-

sure adjustment (1 in Fig. 47) until you obtain the

required pressure (by rotating clockwise the

pressure increases).

10

Turn the boiler off and re---connect the wire to the

modulating operator.

11

Start the boiler and check again the maximum

gas pressure setting.

12

Turn the boiler off and disconnect the gauge.

Important: after the gas pressure checks and any

adjustment operations, all of the test points must be

sealed and replace the adjustment protection cap.

11.4

Checks

Warning: isolate the boiler from the mains

electricity supply before removing any

covering or component.

n

Check the modulation operator coil

1

Remove the front panel of the case.

2

Disconnect the connectors

D

(Fig. 50) from the

modulating operator and measure the electrical

resistance of the coil. Its electrical resistance

value must be approx. 114

Ω

*.

n

Check the on---off operators coils

1

Remove the front panel of the case.

2

Disconnect the electrical connector

E

(Fig. 50).

3

Measure the electrical resistance between the

connector pins of the on---off operators as illus-

trated in Fig. 49.

On---off operator

approx. 4 180

Ω

*

* at ambient temperature.

Fig. 49

11.5

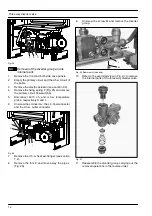

Removal of the gas valve

Warning: isolate the boiler from the mains

electricity supply before removing any

covering or component.

1

Remove the front panel of the case as explained

in the section 2.3 of this manual.

2

Disconnect the connectors

D

and

E

(Fig. 50).

3

Turn off the gas supply and disconnect the gas

isolation cock connector from the inlet port of the

gas valve.

4

Unscrew the connectors

F

and remove the pipe

G

5

Unscrew the screws

H

and remove the valve.

6

Reassemble the valve carrying out the removal

operations in reverse order.

After any service operation on the components of

the gas circuit check all the connections for gas

leaks.

Warning: After cleaning or replacement as

detailed above, if it deemed necessary to

undertake a combustion analysis, refer to

the appropriate chapter

Maintenance

of the

installation instructions manual.

D

E

F

G

H

Fig. 50