28

82.321-M - Pulvasol 1 and 2 / Pulvigne

OPERATIONAL PROBLEMS

PRODUCT FOAMING AND PRESSURE DROP

IF YOU NOTE PROBLEMS, YOU SHOULD CONTACT YOUR BERTHOUD AGENT

ZERO FLOW

POSSIBLE CAUSES

- Suction vannofilter closed .......................................

- Suction vannofilter obstructed ................................

- Air is aspired ...........................................................

- Pump suction valves are dirty or attach to valve seats.

REMEDIES

- Open (figure 1, page 15).

- Remove filter cartridge and clean (fig. 9, page 25).

- Check condition of pipework (cracks, poor sealing

at clamps).

- Remove and clean (figure 13 or 14).

INSUFFICIENT FLOW

- Suction vannofilter is partly obstructed ...................

- Suction pipe tends to crumple ................................

- Air is aspired ...........................................................

- P.T.O. speed insufficient .........................................

- Nozzle type (diameter) and number is too large to

allow pump flow and pressure to reach selected

values .....................................................................

- Pistons are too slac ................................................

- Pump valve seat/valve assemblies in poor condition.

- Clean. Change mesh size if problem continues

(figure 9, page 25).

- Replace.

- Check condition of pipework (cracks, poor sealing

at clamps).

- Check and correct if necessary.

- Check and correct (Chapter Calculating boom flow

per minute, page 12).

- Retighten the diaphragms.

- Check and replace if necessary.

- At suction, the thick mix is an emulsion (air + water).

- If air intake ..............................................................

- At pump ..................................................................

- At delivery ...............................................................

- Check the return pipe (if air inlet).

- Check pipework.

- Vannofilter (figure 9, page 25).

- Pipe crumples.

- Vannofilter is dirty (figure 9, page 25).

- Check condition of springs and valves.

- Check that power take-off speed is correct.

- Leakage in circuit (e.g. parasitic return to lank).

Summary of Contents for PULVASOL 200

Page 2: ...2 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 4: ...4 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 6: ...6 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 10: ...10 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 15: ...15 82 321 M Pulvasol 1 and 2 Pulvigne 3 1 2 2 1 2 3 2 1 3 1...

Page 17: ...17 82 321 M Pulvasol 1 and 2 Pulvigne 1 2 3 4 5 4 3 2 1 4 5...

Page 27: ...27 82 321 M Pulvasol 1 and 2 Pulvigne B P 60 20 B P 105 20 13 14...

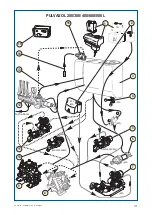

Page 29: ...29 82 321 M Pulvasol 1 and 2 Pulvigne MAINTENANCE DIAGRAMS...