16

82.321-M - Pulvasol 1 and 2 / Pulvigne

OPENING THE VANNOFILTER

(case of sprayers with vannofilter) (

800 L

):

- Make sure that the vannofilter is open (see page 15, figure 1).

POWER TAKE-OFF SPEED:

- With the power take-off connected (following filling), increase its speed to 540 rpm by bringing the needle of

the rev counter opposite the mark (R).

(see manual No. 82.471)

.

ADJUSTING THE VOLUME/HECTARE:

IN ORDER TO PROGRAM YOUR VOLUME/HECTARE

- You need to know, for the gear chosen, the forward speed in km/h, at 540 rpm at the power take-off

(see

manual No. 82.471)

.

- Bearing in mind the required volume/hectare, refer to the rate chart of the selected nozzle(s)

(see

nozzle

manual No. 82.467)

.

- In the column corresponding to the forward speed in km/h, find: the nozzle and pressure which will enable the

required volume/hectare to be obtained.

Example

:

- Speed in km/hour

6 km/h

- Volume/hectare

260 litres/ha

- Selected nozzles

ALUMINE AFX (0.50 m spaced).

Possible combinations:

- ALUMINE AFX BLUE ............3.5 bars 256 litres/ha

- ALUMINE AFX RED .................2 bars 258 litres/ha

You will choose therefore one of the above colours depending on the required nozzle pressure during treatment.

TO OBTAIN REQUIRED VOLUME/HECTARE:

- Fit the chosen nozzles,

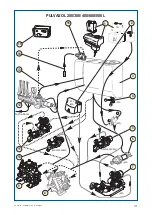

- Put the lever on the main valve in position (2), (figure 4)

- Take power take-off speed to 540 RPM.

- Display on the pressure gauge (1) the pressure previously read from the flow rate table, using the nut (3) on

the controller (5) and lock it with the knurled nut (4). (figure 4)

- From now on, you can work.

SPRAYING:

- With rinsing tank option: place the valves (V3) in position

(figure 8, page 20).

- Set the stopper controlling supply to boom sections in position (1) (figure 5).

- Put the lever on the main valve in position (4) (figure 5).

TO STOP SPRAYING

Total closure:

- Leave the shut-offs in the "OPEN" position (1) and adjust the main valve, putting its handle in position (3)

(figure 5).

Closure of one or more sections:

- Close the plug or plugs by putting them in position (2).

- All the liquid comes out through the top of the valve and returns directly to the tank, or passes through the

hydro-injector

(machines with a hydro-injector)

, thus continuing the agitation of the spraying mixture, but

without passing through the controller.

SPRAYING

Summary of Contents for PULVASOL 200

Page 2: ...2 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 4: ...4 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 6: ...6 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 10: ...10 82 321 M Pulvasol 1 and 2 Pulvigne...

Page 15: ...15 82 321 M Pulvasol 1 and 2 Pulvigne 3 1 2 2 1 2 3 2 1 3 1...

Page 17: ...17 82 321 M Pulvasol 1 and 2 Pulvigne 1 2 3 4 5 4 3 2 1 4 5...

Page 27: ...27 82 321 M Pulvasol 1 and 2 Pulvigne B P 60 20 B P 105 20 13 14...

Page 29: ...29 82 321 M Pulvasol 1 and 2 Pulvigne MAINTENANCE DIAGRAMS...