4.

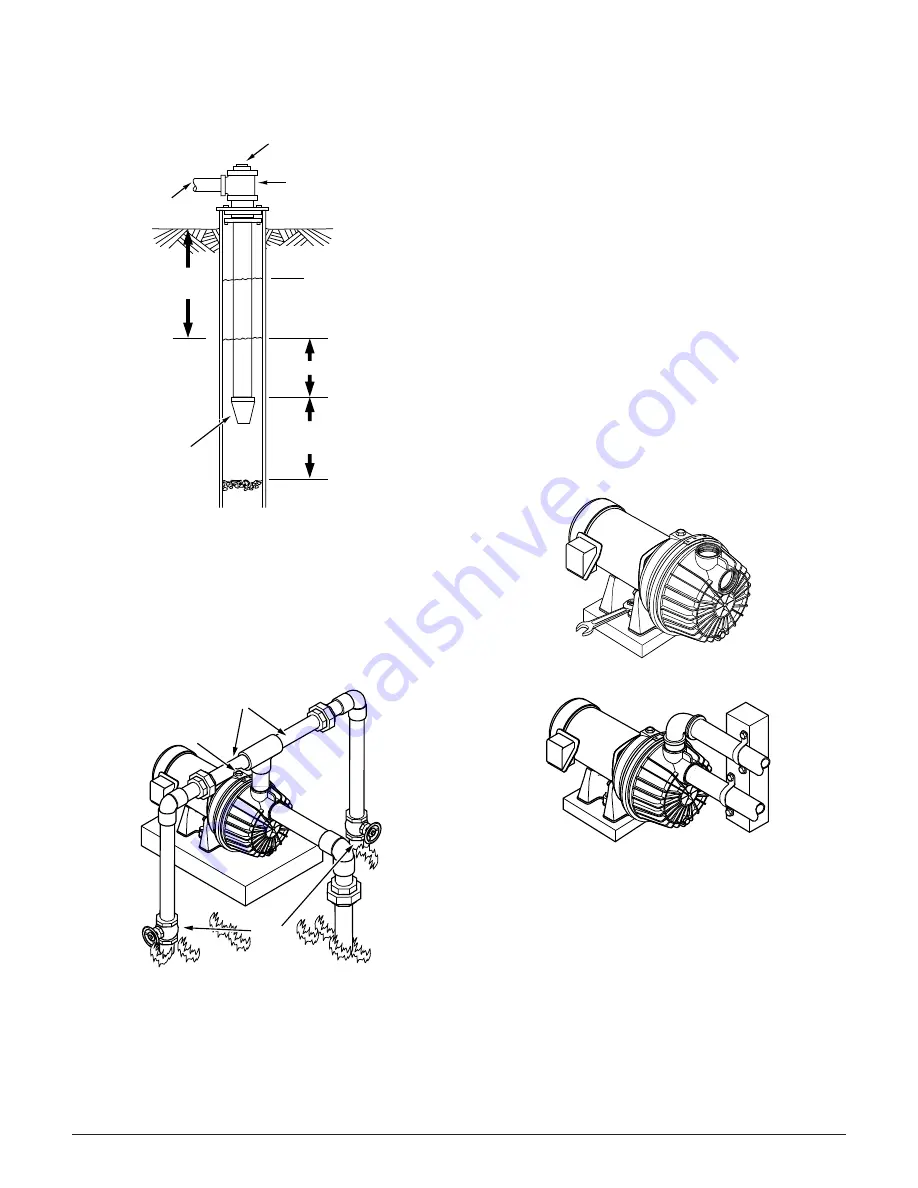

When proper depth is reached, install sanitary well seal

over pipe and in well casing. Tighten bolts to seal casing.

5.

When using foot valve, a priming tee and plug are rec-

ommended (See Figure 1).

Driven Point Installation

1.

Connect suction pipe to drive point (See Figure 2). Keep

horizontal pipe run as short as possible. Use Teflon tape

on male pipe threads. Multiple well points may be neces-

sary to provide sufficient water to pump.

2.

Install check valve in horizontal pipe. Flow arrow on

check valve must point toward pump.

Horizontal Piping From Well To Pump

1.

Pump performance will be decreased if less than 1-1/2”

pipe is used as suction pipe.

2.

To aid priming on well point installations, install line

check valve. Be sure check valve flow arrow points

toward pump.

Discharge Pipe Sizes

Discharge pipe size should be increased to reduce pressure

losses caused by friction on long pipe runs.

• Up to 100' (30.5 m) run: Same size as pump discharge

port.

• 100' - 300' (30.5 - 91.4 m) run: Increase one pipe size.

• 300' - 600' (91.4 - 182.9 m) run: Increase two pipe sizes.

Lawn Sprinkler Application

This pump is designed for lawn sprinkling. Delivers plenty of

water at full sprinkler pressure. Pumps from pond, cistern, or

well points.

Pump discharge can be divided to supply 4 or more sprinkler

systems.

Do not use in booster pump applications.

Pump/Piping Installation

If turning pump on and off by pressure, a pressure switch

and tank are required. For proper installation and operation

instructions, call Customer Service.

Use rigid pipe. Do not use hose or plastic tubing. See “Well

Pipe Installation” for more information.

NOTE:

Use only Teflon tape or Teflon based joint compounds

for making all threaded connections to the pump itself. Make

sure that all pipe joints in the suction pipe are air tight as well

as water tight.

If the suction pipe can suck air, the pump will

not be able to pull water from the well.

1.

Bolt pump to solid, level foundation (See Figure 3).

2.

Support all piping connected to pump (See Figure 4).

3.

Wrap 11⁄2 to 2 layers of Teflon tape clockwise (as you

face end of pipe) on all male threads being attached to

pump.

4.

Tighten joints hand tight plus 11⁄2 turns.

Do not over-

tighten.

5.

Replacing the priming plug with a pressure gauge (pur-

chased separately) will aid in sizing zones, troubleshoot-

ing, and following the pump performance chart.

NOTE:

Install pump as close to well head as possible. Long

piping runs and many fittings create friction and reduce flow.

NOTE:

For long horizontal pipe runs, install a priming tee

between check valve and well head (See Figure 1). For dri-

ven point installations, install check valve. Be sure that check

valve flow arrow points

toward

pump.

3

Suction

pipe

Foot

Valve

Priming plug

Priming tee

Drawdown water

level (pump on)

10-20' (3-6 m)

20' (6 m)

max.

At least 5 feet

(1.5 m)

Standing water

level (pump off)

Figure 1 – Cased/Dug Well

L17

6-35P

Gate

valve

To

service

Priming

plug

Figure 2 – Driven Point

L17

6-35P

Figure 3 – Bolt Pump to Foundation

L17

6-35P

Figure 4 – Support All Piping Connected to Pump