12

STEP 5

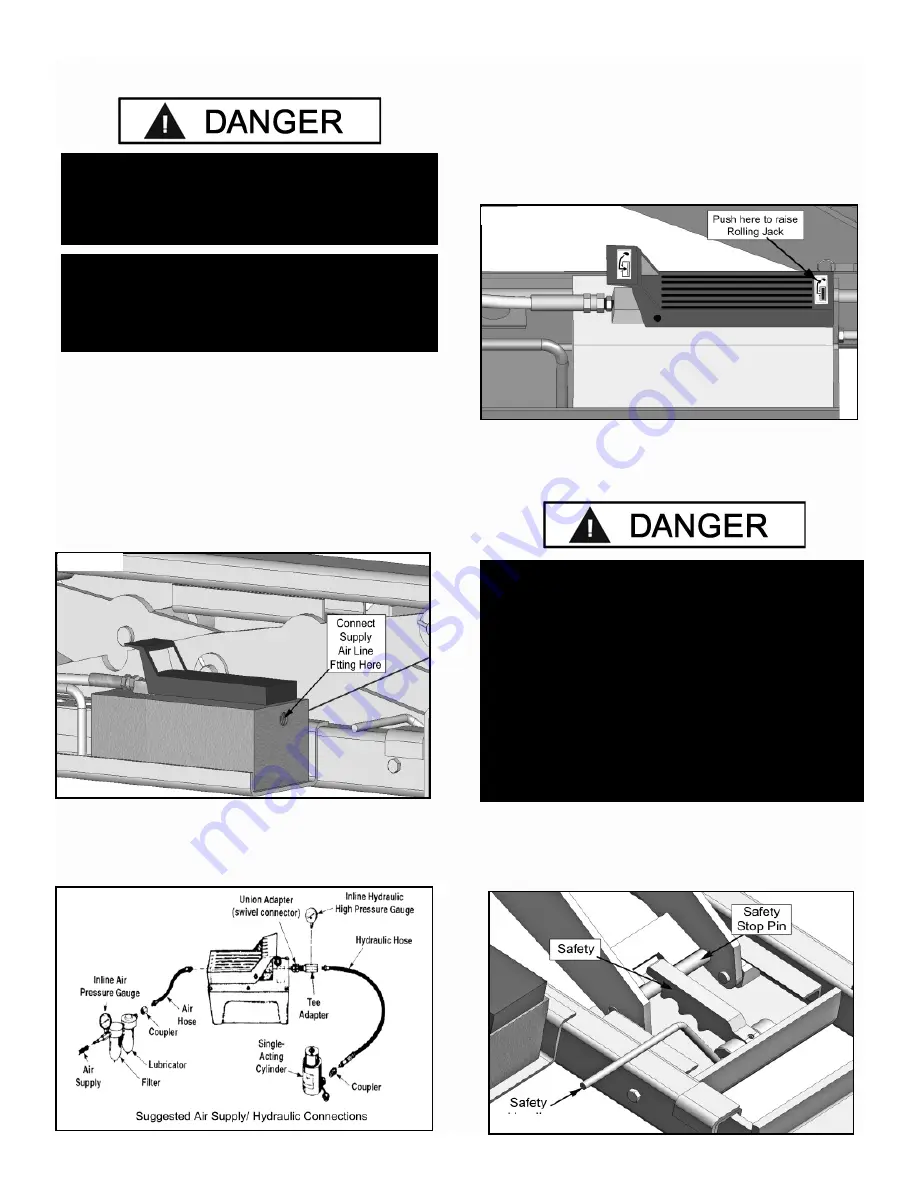

(Connecting Air Supply)

Refer to page 18 if installing with the Optional Rolling

Bridge Jack Airline Kit.

1. Remove the thread protector from the air inlet of the

Pump. Select and install the threaded

fi

ttings (not

supplied) which are compatible with your air supply

fi

ttings. The air supply should be 20 CFM / 57 M3/MIN)

and 100 PSI (7 BAR) to obtain the rated hydraulic pressure.

Air Supply should be regulated to a maximum of 125 PSI (8.6

BAR) (See Fig. 5.1)

2. An appropriate air line regulator, water separator and

lubricator should be installed on the Air Supply line. The

absence of these items will void the warranty on pneumatic

components. (See Fig. 5.2)

STEP 6

(Start Up / Final Adjustments)

1. Raise the Jack

WITHOUT

a vehicle to check for proper

operation of the Rolling Bridge Jack.

2. Depress the Pedal on the lifting end to raise the Jack

through the full range of the Jack. (See Fig. 6.1)

Under certain circumstances it may be necessary to prime

the Air Hydraulic Pump Unit. Refer to the manual that came

with the pump for these instructions.

3. Lower the Jack onto the nearest Safety Stop Pin. When

the Jack is loaded with a vehicle make sure the Jack is

resting on the Safety Stop Pin prior to performing any work

on the vehicle. (See Fig. 6.2)

DANGER!

THE AIR SUPPLY SHOULD BE TO

20 CFM (.57 M3/MIN.) AND 100 PSI (7 BAR).

AIR SUPPLY SHOULD BE REGULATED TO A

MAXIMUM OF 125 PSI (8.6 BAR)

DANGER!

DISCONNECT AND / OR RELEASE THE PRESSURE

FROM THE AIR SUPPLY SYSTEM / HOSES BEFORE

PERFORMING ANY INSTALLATION OR MAINTENANCE

OF THE AIR SUPPLY SYSTEM.

DANGER!

VISUALLY CONFIRM THAT ALL PRIMARY

SAFETY LOCKS ARE ENGAGED BEFORE

ENTERING WORK AREA.

Suspension components used on this Jack are

intended to raise and lower the Jack only and are not

meant to be load holding devices. Remain clear of

elevated Jack unless visual confirmation is made that

all primary Safety Locks are fully engaged and

the lift is LOWERED onto the Safety Locks.

Refer to installation /operation manual for proper

Safety Lock procedures and /or further instruction.

Fig. 5.1

Fig. 5.2

Fig. 6.1

Fig. 6.2

Summary of Contents for RJ-12

Page 2: ...2 This page intentionally left blank...

Page 10: ...10 Fig 3 2...

Page 16: ...16...

Page 20: ...20...