8

9. Remove and discard the o-ring (12) from the relay

piston (13).

10. Remove and discard dust shield (16), if fi tted, and the

retaining ring (15) from the valve cover (2), then remove

and discard the exhaust piston (17 or 17A).

11. Remove and discard the exhaust piston o-ring (18) and

the exhaust diaphragm (19), if fi tted.

12. Remove and discard the service piston (20) and its

o-ring (21) from the valve cover (2).

13. Remove the spring (22) and spring cage (23) from the

valve cover (2). Discard the spring and retain the spring

cage.

14. Use shop air at the control port to extract the blend back

piston from the valve cover (2). Retain the blend back

piston (24), then remove and discard both o-rings (25

& 26).

15. Remove and retain the proportioning piston (28) from

the valve cover (2), then remove and discard both

o-rings (27 & 29).

16. While holding the inlet valve seat (32) in place, remove

and discard the retaining ring (30) from the proportion-

ing piston (28).

17. Remove the inlet valve seat (32), the inlet valve (33),

and the valve spring (34) from the proportioning piston

(28), then remove and discard the o-ring (31) from the

valve seat (32). Discard the valve and spring (33 & 34)

also.

18. Remove and discard the exhaust cover screw (36) and

exhaust cover (37).

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all metal parts. Do not damage bores

with metal tools.

2. Wash all non-metallic components (key nos. 4, 12, 17,

20, 23, 24, 28, 32) in a soap and water solution making

certain to rinse and dry thoroughly.

3. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pitting and cracks.

Superfi cial corrosion and/or pitting on the exterior por-

tion of the body (1) and cover (2) is acceptable. Replace

the entire valve if the interior of the body or cover exhibit

signs of corrosion or pitting.

4. Inspect each non-metallic component for cracks, wear

or distortion. Replace the entire valve if these conditions

are found.

5. Inspect the bores of both the body (1) and cover (2)

for deep scuffi ng or gouges. Replace the entire valve if

either are found.

6. Make certain the air channel running between the top

surface of the body (1) and its supply port is clear and

free of obstruction.

7. Make certain all air channels and exhaust passages in

the valve cover (2) are clear and free of obstruction.

8. Inspect the pipe threads in the body (1) and valve cover

(2). Make certain they are clean and free of thread

sealant.

9. If the valve was equipped with a relay piston spring

(14), inspect it for signs of corrosion, pitting and cracks.

Replace as necessary.

10. Inspect all air line fi ttings for corrosion and replace

as necessary. Make certain to remove all old thread

sealant before reuse.

ASSEMBLY

1. Prior to assembly, lubricate all o-rings (identify by using

Figure 11), seals, and pistons as well as body and cover

bores, using the lubricant provided with the Bendix

maintenance kit. Use all of the lubricant and spread it

evenly on the rubbing surfaces.

2. Install the o-ring (31) on the inlet valve seat (32).

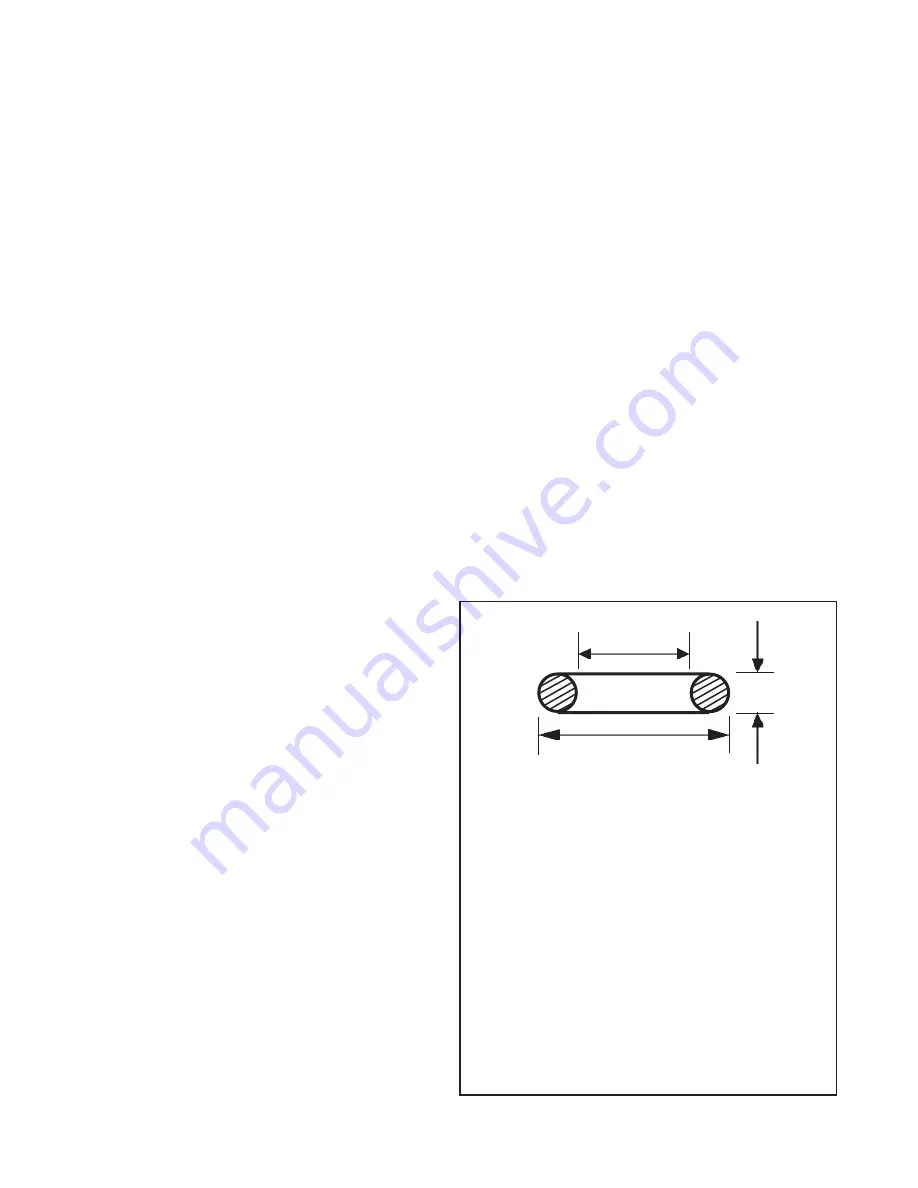

O-RING IDENTIFICATION

KEY NO.

I.D.

O.D.

W

5

.8620

1.068

.103

6

1.424

1.630

.103

11

3.487

3.693

.103

13

3.234

3.512

.139

18

1.356

1.496

.070

21

1.176

1.316

.070

25

1.112

1.318

.103

26

.7370

.9430

.103

27

.4120

.5520

.070

29

.7390

.8790

.070

31

.4890

.6290

.070

FIGURE 11 - O-RING IDENTIFICATION

I.D."

O.D."

W"