11

3. Install the spring (36) on the inlet seat (37) so that the

small diameter fits over and around the air passage

through the center of the inlet seat.

4. Install o-ring (33) on the check valve seat (32).

5. Using a small amount of grease applied to the check

valve (34) and guide (35) to secure both items to the

check valve seat (32). Gently insert the assembled

items into the valve cover (3). Install the valve guide

(35) so that its flange contains (surrounds) the coils of

the large end of the spring (36), when the valve seat

(32) is installed in the cover (3). Make certain that the

guide (35) is centered over the spring (36), which was

installed in step 3. Note; The check valve must be

installed so that the top hat portion fits into the valve

seat (32).

6. Install the small and large diameter o-rings (27 & 28) on

the check valve seat (23).

7. Install the spring (26) on the inlet seat (29) so that the

small diameter fits over and around the air passage

through the center of the inlet seat.

8. Install the check valve (24) and valve guide (25) in the

check valve seat (23). Note: The check valve must be

installed so that the top hat portion fits into the valve

seat (23). Install the valve guide (25) so that its flange

contains (surrounds) the coils of the large end of the

spring (26), when the valve seat (23) is installed in the

cover (3). Use a small amount grease to hold these

parts in the valve seat (23).

9. Install the assembled valve seat (23) with the check

valve and valve guide (24 & 25) into the cover (3) bore

and while holding it in place install the retaining ring

(22). Make certain the retaining ring is fully seated in

its groove.

10. Install the valve retainer (10) on the inlet and exhaust

valve (11) so that the flange of the retainer (10)

surrounds the rubber portion of the valve. Install the

inlet and exhaust valve in the body (4).

11. Install the inlet and exhaust valve return spring (9) in

the body (4).

12. Install the large and small diameter o-rings (7 & 8) in

the exhaust cover (6), then install the exhaust cover in

the body (4) taking care not to damage the o-rings. Hold

the exhaust cover in place.

13. While depressing the exhaust cover (6), install the

retaining ring (5) in the body (4). Make certain the

retainer (5) is fully seated in its groove in the body.

14. If the valve was equipped with a relay piston return spring

(20), install the spring in the body, large diameter first.

15. Using lubricant to hold them in place, install the large

and small sealing rings (18 & 17) on the cover (3).

16. Install the o-ring (21) on the relay piston (19), then install

the piston in the body (4).

17. Note the relationship marks made prior to disassembly,

then install the cover (3) on the body (4). Secure the

cover on the body using the two, short cap screws (16).

Again, noting the relationship marks, secure the bracket

(15) on the cover (3) and body (4) and using the two

long cap screws (12) and two nuts and washers (13).

Torque the four cap screws to 120 to 150 lb. in.

18. Install the two cap screws (14) that secure the bracket

(15) to the cover (3) and torque to 180 - 220 pound

inches.

19. Noting the relationship marks made during

disassembly, secure the controller (1) or cover plate to

the cover (3) using the four cap screws (2). Torque

the four cap screws to 50-80 pound inches.

20. Install all air line fittings and plugs making certain thread

sealing material does not enter the valve.

Install the rebuilt valve on the vehicle and perform the

OPERATION AND LEAKAGE TESTS before placing the

vehicle in service.

Key Description Qty.

I.D.

O.D.

W

7

O-Ring

1

1.424 1.630 0.103

8

O-Ring

1

0.862 1.068 0.103

18

O-Ring

1

3.487 3.693 0.103

21

O-Ring

1

3.234 3.512 0.139

27

O-Ring

1

1.362 1.568 0.103

28

O-Ring

1

1.114 1.254 0.070

30

O-Ring

1

1.356 1.496 0.070

31

O-Ring

1

1.176 1.316 0.070

33

O-Ring

1

1.176 1.316 0.070

38

O-Ring

1

1.176 1.316 0.070

39

O-Ring

1

0.801 0.941 0.070

40

O-Ring

1

0.739 0.879 0.070

12345

12345

12345

12345

12345

1234

1234

1234

1234

1234

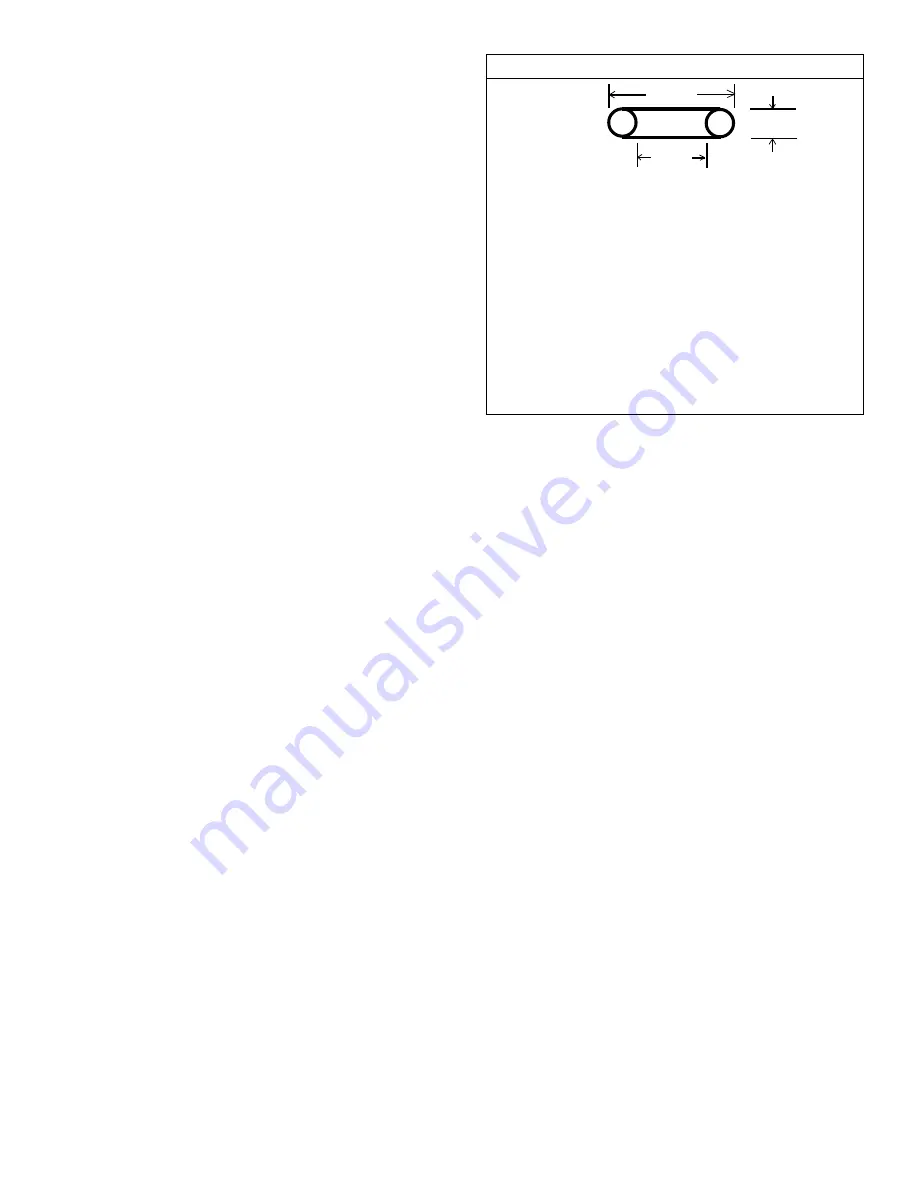

W

O.D.

I.D.

O-RING IDENTIFICATION