*

Date of issue

Version

Imprint:

BEMO SYSTEMS GmbH

Max-Eyth str. 2

74532 Ilshofen-Eckartshausen

18.02.2019

02

Read carefully and

keep for future use!

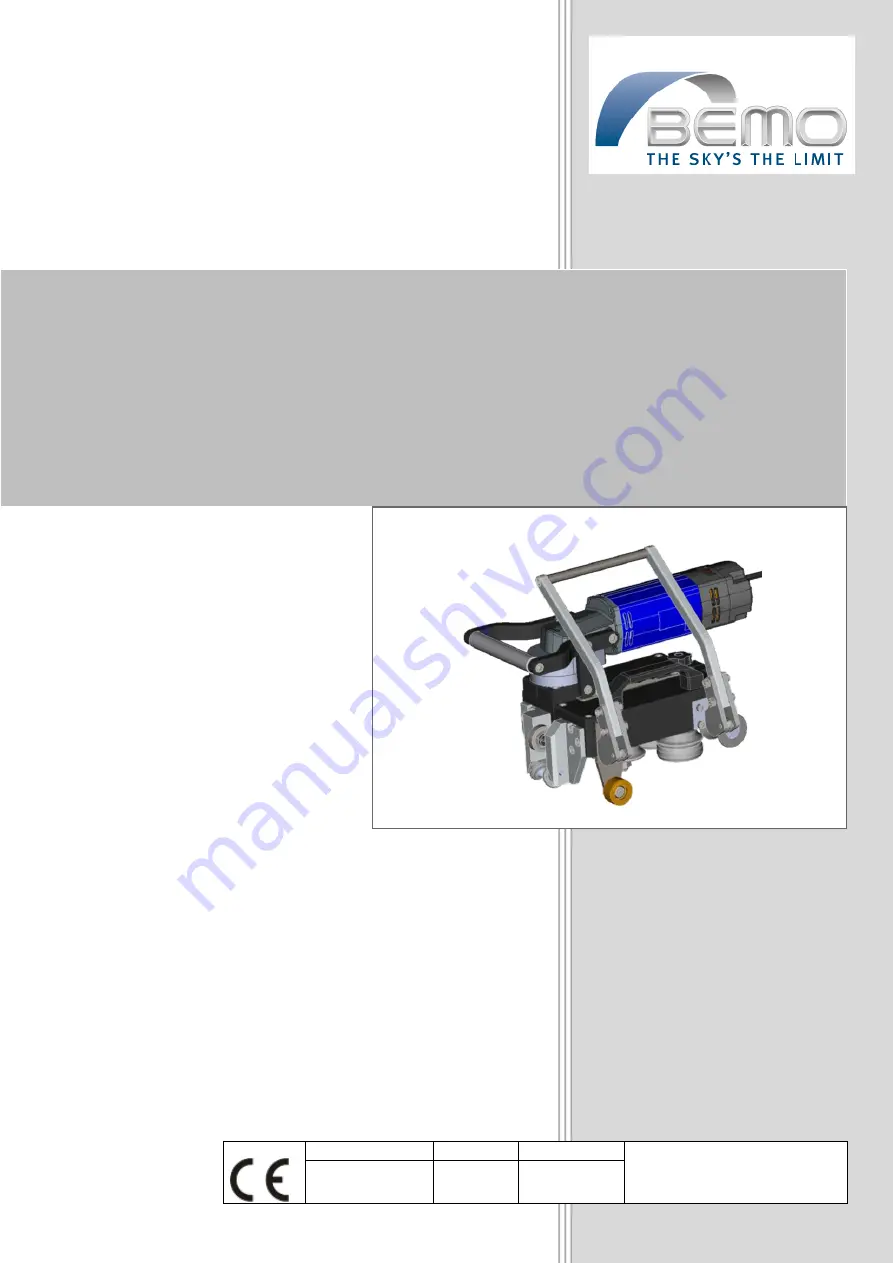

Original operating

instructions of the Seaming

Machine for BEMO

standing seam profiles

types: N65 / N50 / VF65

Type II (esma)