7

4. SYSTEM DESIGN FOR HAZARDOUS AREA

4.1 System certificates

In addition to the ATEX EC-Type Examination

Certificate, ITS have issued two system

certificates. One defines how the BA338C may be

used with Zener barriers and the other with

galvanic isolators. Both are divided into two

sections to cover input signal sources in the

hazardous and in the safe area.

Interface Certificate No

Zener barriers

Ex01E2005

Galvanic isolators

Ex01E2006

This section interprets these system certificates

and illustrates how to design systems with Zener

barriers and galvanic isolators.

System certificates are Certificates of Conformity

which are primarily issued for guidance in the UK.

They do not form part of certification to the

European ATEX Directive.

4.2 Use with Zener barriers

Zener barriers are the least expensive intrinsically

safe interface between a safe and hazardous area.

However they do not provide isolation and require

a high integrity earth connection that may be

expensive to install. For a single BA338C it may

be less expensive and complicated to use galvanic

isolators when a high integrity earth connection is

not already available.

Any certified Zener barriers may be used with the

BA338C providing their output parameters do not

exceed the input parameters of the terminals to

which they are connected. Only one polarity of

Zener barrier i.e. positive or negative , may be

used with an instrument.

To assist with system design, the Zener barrier

system certificate specifies the maximum cable

parameters for popular barriers and lists some of

the diode return barriers that may be used.

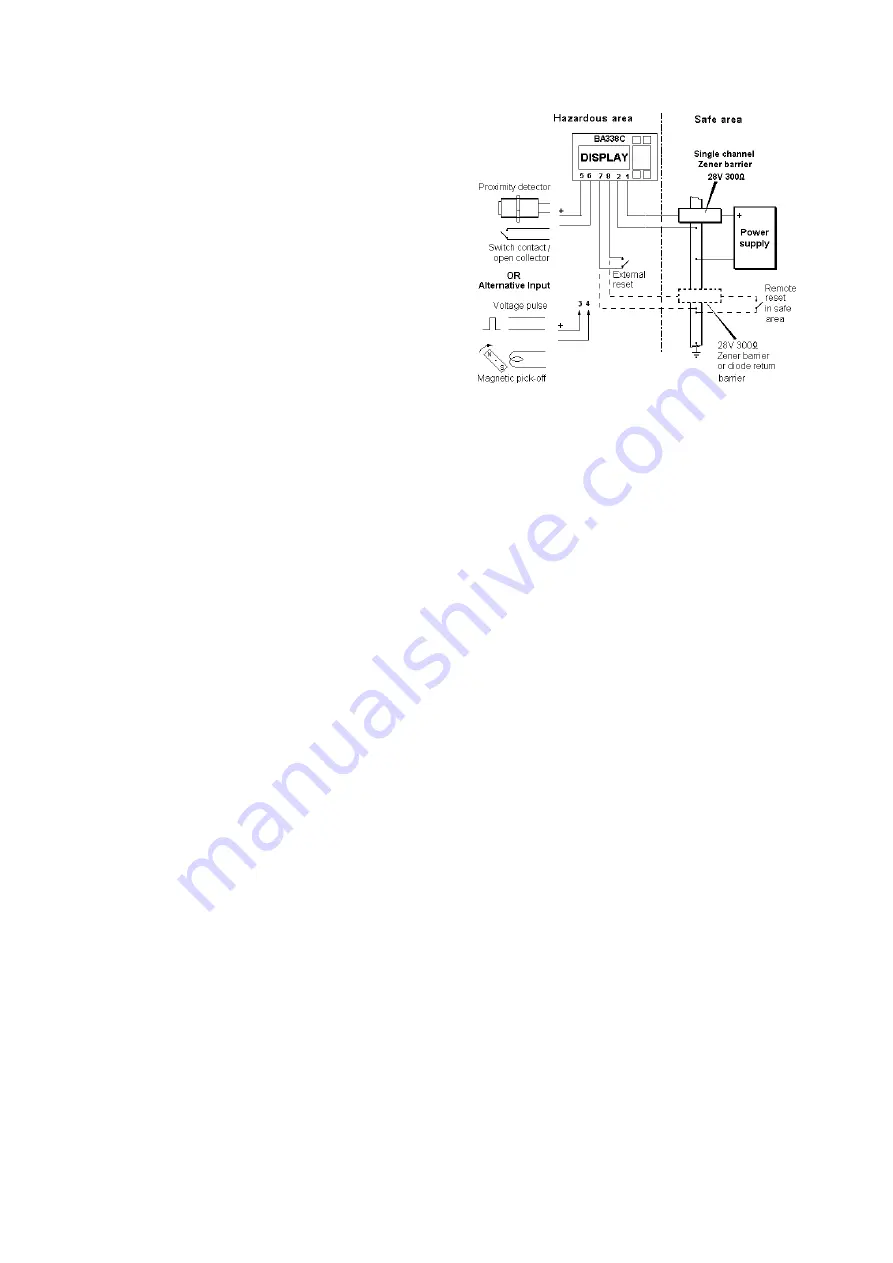

Fig 2 illustrates the basic circuit that is used for all

BA338C installations protected by Zener barriers.

For simplicity, connections for the optional pulse

output, 4/20mA output and backlight are included

in the appendix to this manual.

Fig 2 BA338C used with Zener barriers

Alternatively the pulse source may be located in

the safe area. Fig 3 shows how an additional

Zener barrier is used to transfer the signal to the

rate totaliser in the hazardous area. When more

than one Zener barrier is used in a system all must

have the same polarity. i.e. all positive or all

negative barriers.

When designing a system it is important to

remember that terminals 2, 4, 6 and 8 are

interconnected within the BA338C - see Fig 1.

4.2.1 Power supply

Usually a BA338C rate totaliser is powered from

the safe area via a positive polarity 28V 300

Ω

Zener barrier, which has an end-to-end resistance

of about 340

Ω

. When used with a proximity

detector input the BA338C consumes

approximately 25mA and requires a minimum

voltage of 10V between terminals 1 and 2. The

supply voltage in the safe area must therefore be

between 18.5V and the maximum working voltage

of the Zener barrier – usually about 26V.

4.2.2 Pulse input

As shown in Fig 2 the BA338C will count pulses

from a wide variety of sources in the hazardous

area, or from the safe area as shown in Fig 3.

Terminals 5 and 6 are for pulse sources that need

powering e.g. a switch contact, an open collector

or a 2-wire NAMUR proximity detector.

Terminals 3 and 4 are for voltage pulse inputs.

Note:

Only one input may be used at a time. i.e

pulses can not be counted at terminals 3 & 4 and

at 5 & 6 at the same time.

No Zener barrier is required in series with the input

if the intrinsically safe pulse source is located

within the hazardous area.

The following table shows the switching thresholds

for the various transducers, plus the maximum