15

The delete break-point sub-function

dEL

operates

in exactly the same way as the

Add

sub-function

described above.

Once within the

dEL

sub-

function each time the

(

button is pressed a

break-point is removed. When deleting a break-

point from a calibrated indicator, the break-point to

be deleted can be selected using the

&

and

*

push buttons.

The minimum number of break-

points is 2, break-points

0

:1

and

1

:1

.

When the required number of linearising break-

points has been entered, return to the linearisation

sub-menu by pressing

)

.

The indicator will

display the

Add

or

dEL

prompt depending upon the

last function used. Using the

Pt5

sub-function the

input current at which each break-point occurs and

the corresponding indicator display may now be

defined.

Using the

&

or

*

button select the

Pt5

function

in the sub-menu and press

(

to enter the function

which will display the first break-point

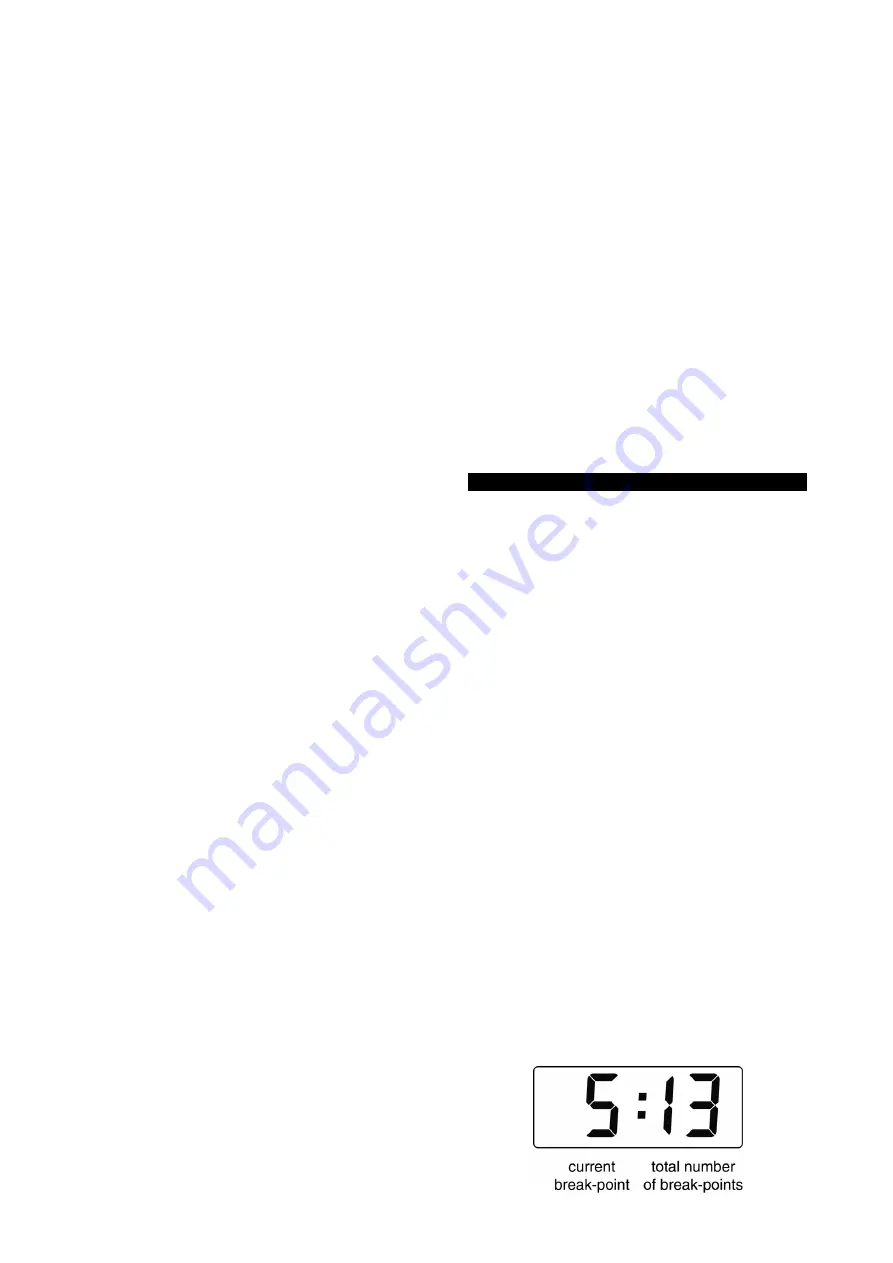

0 : n

, where

n

is the total number of linearising break-points

entered - see Fig 10.

The selected linearising

break-point can be changed using the

&

and

*

buttons. When the required linearising break-point

has been selected set the indicator input current to

the exact value at which the break-point is required

and press

(

*

. Using the

&

or

*

button and the

(

button to move between digits, enter the

required indicator display at this break-point.

When set as required, press the

)

push button to

enter the required indicator display and return to

the sub-menu from which the next break-point can

be selected.

When all the break-points have been calibrated

pressing

)

twice will return the indicator to the

‘CAL’ function in the configuration menu.

Note: *

The indicator input current must be

adjusted to the required value before the

(

button is operated to enter the required

indicator display.

Error message

If during calibration the indicator displays

a

FAiL

error message the current at which

the selected break-point is being set is not

above the proceding break-point or is not

below the following break-point.

6.1.1

Example

Adding break-points to a new indicator.

When adding break-points to a new indicator, or to

a lineariser following resetting to the factory

defaults using the

LtAb

function described in

section 5.11, each additional break-point should be

added before the highest existing breakpoint.

The first additional break-point should be added

before the default break-point

1 :1

which will result

in a display of

1 : 2

. If more new break-points are

required, using the

*

button select the new

highest break-point

2 : 2

and add the second

additional break-point by operating the

(

push

button which will result in a display of

2 : 3

. Repeat

the sequence until the required number of break-

points has been entered.

The input current at which each break-point occurs

and the corresponding indicator display may now

be entered as described above.

6.2

Lineariser calibration using the internal

reference.

The

5Et

function enables the lineariser to be

calibrated without the need for an accurate

external

current

source.

Throughout

the

calibration the indicator input current may be any

value between 4 and 20mA.

The

5Et

functions contains four sub-functions.

Display

Summary of function

Add

Add a break-point

Adds a new break-point before the

displayed break-point. The calibration of

existing break-points is not changed, but

the

identification

number

of

all

subsequent break-points is increased by

one.

dEL

Remove a break-point

Removes the displayed break-point and

joins the preceding segment to the

following segment with a straight line.

The

identification

number

of

all

subsequent break-points is decreased by

one.

in

Defines the current at which break-point

occurs.

Enables the required current at each

break-point to be defined without having

to input an accurate input current to the

indicator.

di5P

Defines indicator display at break-point.

Enables the indicator display at each

break-point to be defined.

The number of break-point required should first be

entered using the

Add

and

dEL

sub-functions. In

both these sub-functions the indicator initially

displays the current break-point and the total

number of break-point being used as shown below.