8. Push die out onto die cart.

9. Reverse procedure to install die.

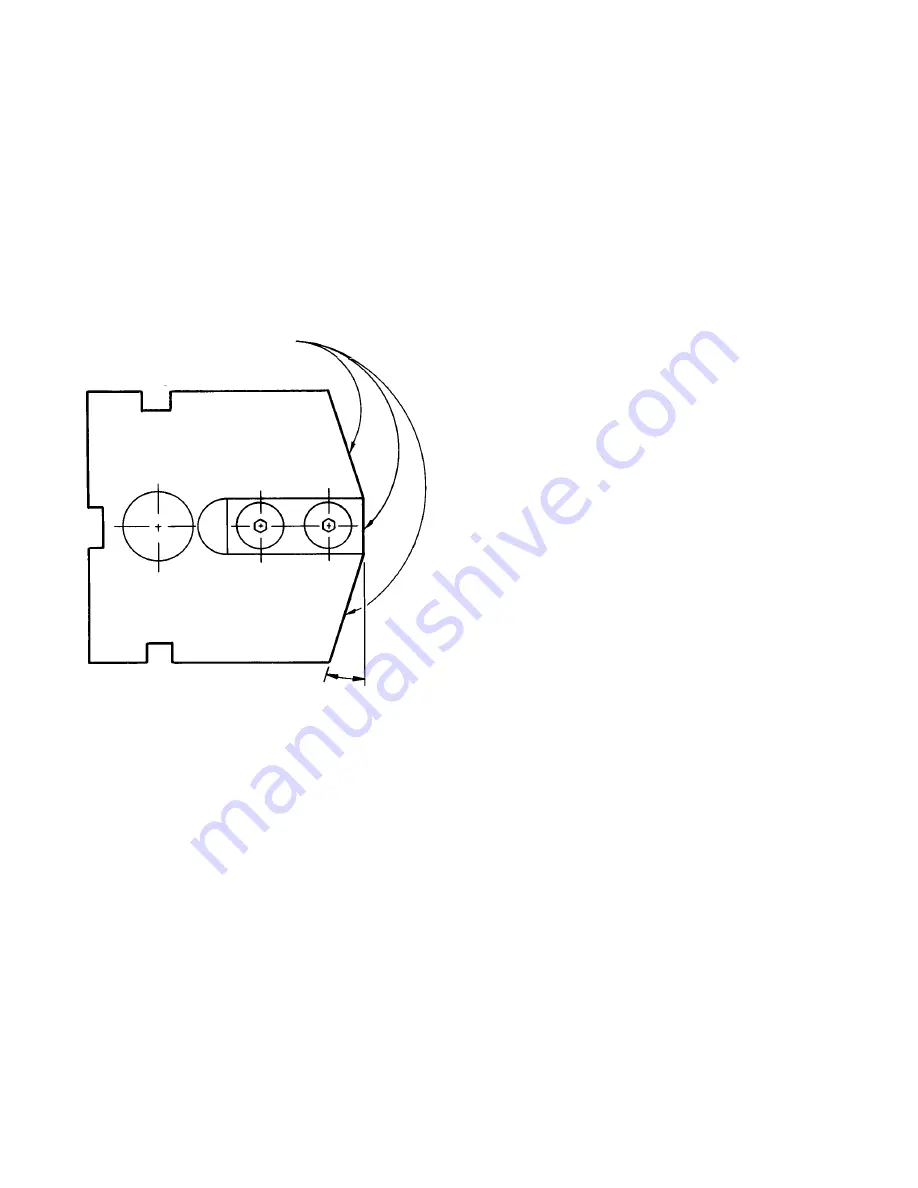

INSTRUCTIONS FOR SHARPENING TEETH

Remove the entire die from the press as a unit and sepa-

rate it into a top and bottom die set. Keep all teeth

attached to the die plates, however, the die shoes may be

removed from the die plates for ease in grinding teeth.

The stripper plates and urethane stripper plugs must be

removed before the teeth are ground. Grind teeth of the

top and bottom as a unit. Teeth shall be ground on tops

and both adjoining angled sides. The sides are ground

at an angle of 9° or 18°, depending on machine model.

This angle is not critical, however, both sides should be

the same. The die may now be reassembled and placed

back into the machine. The die and press each have a

marking labeled “Front”. The die is symmetrical, but it

should be placed back in the press as originally assem-

bled. If grinding equipment is not available to sharpen

teeth as a unit, they may be ground individually. Read

the instructions for the procedure to remove and replace

teeth.

PROCEDURE FOR REPLACING TEETH

OR OTHER PARTS OF THE DIE

Remove the die from the press as a unit and separate it

into the top and bottom die sets. Next, remove the strip-

per plates and and urethane stripper plugs, tooth clamps

and rod. Teeth that need replacing may now be lifted off

the die plate. In replacing new teeth, it is very important

that all parts be cleaned thoroughly, making certain that

no lint from wiping rags or other foreign material gets

between the teeth. A spare tooth should be used for indi-

vidually checking clearance between all teeth. This clear-

ance should be .002” (0.05mm) minimum to .007”

(0.18mm) maximum around all parts of mating teeth.

After the clearance is determined to be correct, the teeth

in the bottom die set should be securely fastened by

means of the clamps and rod. The nuts on the rod

should be tightened with a torque wrench to 120 foot

pounds (163 N-M).

The two sets of set screws in each end keeper should

also be tightened at this time. These are locked in

placed with a second set of socket head set screws. The

teeth in the top die set should be tightened securely with

the rod, but only tight enough with the clamps to hold

them in place so they are allowed to move for adjustment

after the top and bottom die sections have been slipped

together. The top and bottom die sections should be

slipped together without the urethane stripper plugs and

stripper plates. At this time, clearance between top and

bottom mating teeth should be checked and adjusted if

necessary. This adjustment can be accomplished by

means of the set screws in the keepers on both ends of

the top die section. After it is determined that the die

meshes properly, the clamps of the top die should be

tightened and the urethane stripper plugs and stripper

plates replaced in the die. The entire die may now be

returned to the press.

PROCEDURE FOR REPLACING CYLINDER SEAL

1. Remove the urethane roller (615059) from one side of

the press.

2. Remove the top and bottom bolts holding the com-

plete die in place, and remove the complete die unit

from the press.

3. Remove the screws that secure the ram plate to the

pistons and then remove both ram plate skirts

(616113) and the ram plate (616112).

4. Bolt a long bar or pipe to the piston (616002) - there is

one threaded hole in the top of each piston. Remove the

piston upward from the cylinder (616099).

5. Replace the defective seal (3308009) in the cylinder,

with the lips of the seal pointing downwards.

Lubricate the seal for easier assembly.

6. Also, check the “O”ring #331 (2748014), under the

cylinder, for leakage and replace as required.

7. Reverse steps 1, 2, 3 and 4 to assemble. When

replacing pistons, apply pressure downwards as

evenly as possible so that lips of the seals will not be

cut or damaged.

HOLE PUNCH FOR SPLICE DETECTION

For strip joining dies equipped with a hole punch assem-

bly, 1½” or 2” (38mm or 51mm) diameter on the exit side

of the die, you can sharpen the round punch portion and

the die plate one or more times until a total of 0.075” to

0.100” (1.9mm to 2.5mm) maximum has been removed,

depending upon the thickness of the material being

joined. The following spare parts can be ordered by

complete description and you must indicate the diameter

of the hole punch, press model number and serial num-

ber.

1. Spare hole punch and die plate. (You will need to

locate and drill dowel pin holes to properly match up

the new mating punch and die plate.)

2. Urethane stripper ring (616270) over the hole punch

for splice detection assembly.

Original Length 2.500” (63.5mm)

Sharpen these three surfaces.

Do not grind off more than .060” (1.5mm)

total during successive sharpenings.

F-13569-5

Rev. 7-5-05 5-15-80

2

9° or 18° depending on machine model.