Supplied By www.heating spares.co Tel. 0161 620 6677

Installation Instructions – Page 4

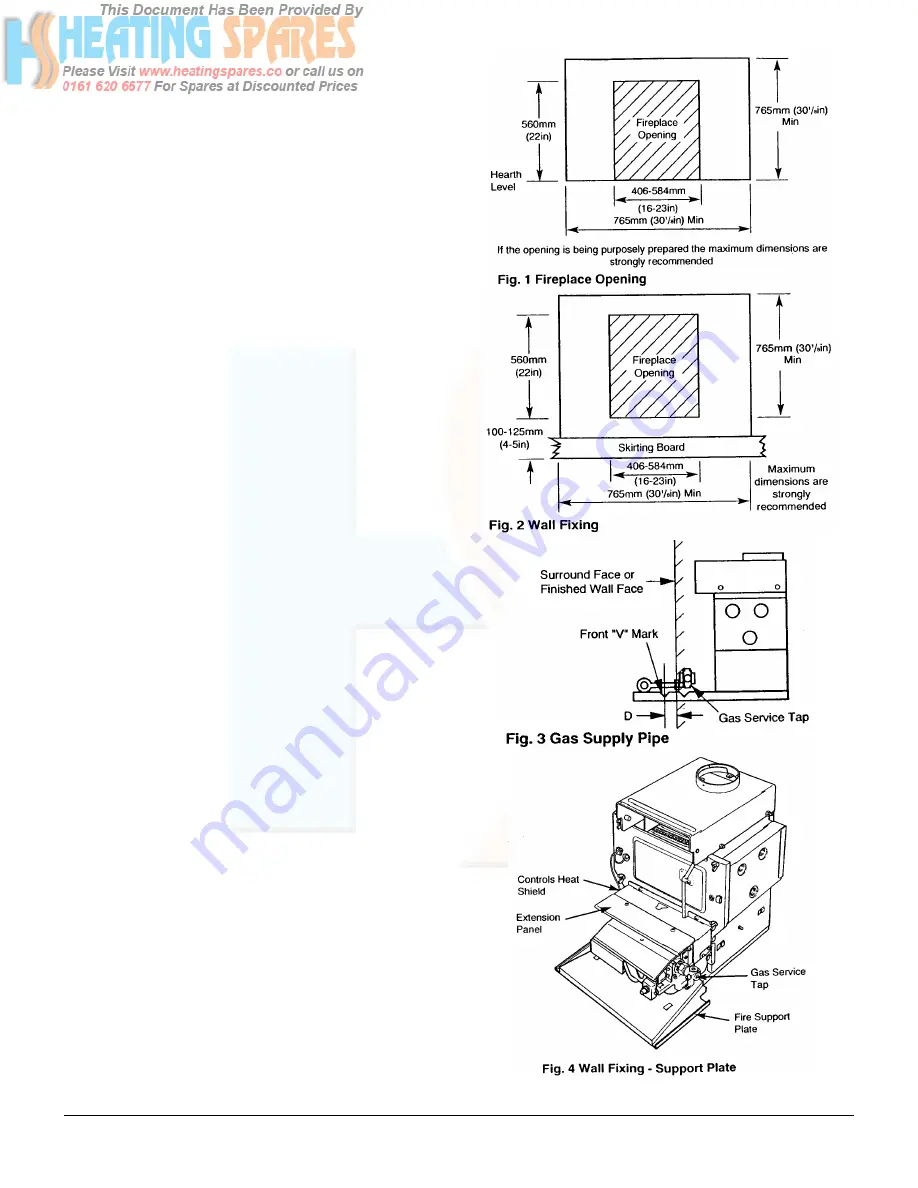

GAS SUPPLY

1. The gas supply is provided from the service tap on the boiler

unit. A supply pipe is provided with the fire. This pipe has one

flared end for connection to the fire and a plain end which is

connected to the service tap by a nut and olive.

2. Dependent upon the position of the boiler relevant to the

surround or wall finish face, it may be necessary to shorten the

supply pipe. IF THE PIPE HAS TO BE SHORTENED CARE

MUST BE TAKEN. The length of the supply pipe is determined

as follows:

(a)

Measure the distance ‘D’ from the centre of the front

positioning ‘V mark on the boiler tray, back to the

surround face or finished wall face (Fig.3).

(b)

FROM THE PLAIN END of the supply pipe cut off a

length of pipe equal to the distance ‘D’ measured

above. Take care to ensure that the cut is square

and the pipe is free from burrs and swarf.

ALTERNATIVELY

(c)

The amount of pipe required to be cut off can be

determined by holding the PLAIN END of the pipe

against the surround or finished wall face, marking

the pipe at the position of the centre of the front

positioning ‘V mark on the boiler tray.

3. After threading the steel flare nut on the above pipe, connect

the plain end to the service tap with the remaining nut and olive.

It is important to ensure that the flared end of the pipe:

(a)

Faces to the right.

(b)

Is parallel with the hearth or floor.

4. It is necessary to unscrew and remove the extension plate

from the boiler controls heat shield. Once removed this item can

be discarded (Fig.4).

Fitting the Fire

HEARTH FIXING

1. Fit the fire backing plate to the fire using the M5 x 8mm

thread forming screws provided (Fig.5).

2. Locate the fire spigot into the draught diverter on the boiler.

Push the fire backwards until the backing plate touches the

surround or finished wall face. Adjust the feet to level the fire

(Fig.6).

3. Mark the position of the most suitable pair of securing holes

in the fire backing plate (Fig.5) and remove the fire. Drill and

plug the wall with suitable plugs. Replace the fire and secure to

the wall with suitable fixing screws.

4. Connect the supply pipe to the fire inlet connection.

WALL FIXING

1. Slide the fire support plate over the overhanging boiler base

(Fig.4). Using the screws provided, loosely attach the plate

using the slots at each side.

2. On electronic control boilers it will be necessary to remove

the input plug from the controls. Push the support plate

backwards until it touches the wall surface and tighten the

screws to lock the frame in position. Locate the fire spigot into

the draught diverter on the boiler. Push the fire backwards until

the backing plate touches the finished wall face. Adjust the feet

to level the fire (Fig.6).

3. Mark the position of the most suitable pair of securing holes

in the fire backing plate (Fig.5) and remove the fire. Drill and

plug the wall. Replace the fire and secure to the wall with the

two fixing screws provided.

4.Connect the gas supply pipe to the fire inlet connection.