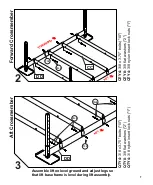

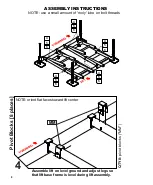

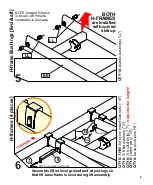

Assembly Instructions

.........................................................................Pages 6 - 17

First Use / Adjustments

..……………...........................................................Page 18

Basta Marine Boat Lift Accessories

....…………………............….….….Page 23

Parts List and Diagrams

..................................................................Pages 4 - 5, 19

Troubleshooting / FAQ

Maintenance

.…...........................................................................Page 21

......................…...........................................................................Page 20

2

INDEX

Warning

......………………..............................................................................Page 2, 3

Warranty

.............................…...........................................................................Page 22

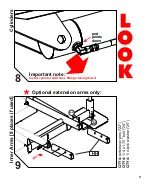

NOTE:

Your boat lift is a very heavy piece of equipment. Improper use could result in

serious injury or death. For the safety of people and property please review the safety

guidelines below for your new boat lift.

Do not exceed the maximum weight capacity

specified for the lift. SEE PAGE 17.

Passengers should stand clear of the lift and not

be aboard when the lift is in operation.

Do not play on or near the lift.

Leave your automatic bilge pump turned on the

automatic setting to prevent the accumulation of

rain water.

Service your lift regularly.

Do not service the unit with the boat on the lift.

Use a mooring line for additional security.

Only use Basta Marine approved oil in lift.

Special biodegradable non-toxic hydraulic fluid

Visually inspect all parts and assemblies for

defects and damage prior to assembling the

lift.

Do not install the lift alone.

Install the lift on firm and level ground.

Verify the lower frame of the lift is level

before each use.

Turn the power off during periods of non-use.

This hoist is a heavy piece of equipment please

use with care.

The lift should not be used for any other

purpose besides the lifting of boats & watercraft.

WARNING

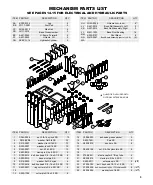

part #

Y354-0001

Manufactured under one or more of the following patents:

#4895479, #4900187, #5143182, #5184914, #5311970,

#6318929, #6602022, #6837651,

#7021861, #7210420,

#7712425, #D503692 Canada #2089044

Other patents pending

P A T E N T E D

D E S I G N

Do not exceed the maximum weight capacity

specified for the lift.

4,000 LBS

DANGER

MAXIMUM CAPACITY

T O T A L

B O T H

L I F T S

before each use.

3

In the following pages various symbols are used:

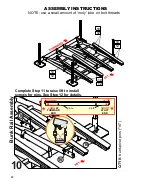

indicates an illustration for a procedure.

indicates a major part described in the parts list on pages 4 and 5.

or indicate hardware items shown above and described in the parts list

on pages 4 and 5.

1&2

23

AA

1

After the lift is assembled and installed, all

fasteners should be checked for proper tightness

and reinspected periodically.

INSPECT

the lift monthly

for frayed hoses, loose

fasteners and corrosion

Before Using:

Read this manual

completely!

!

!

!

lift unattended

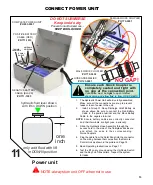

OIL INJECTED INTO THE SKIN FROM HIGH PRESSURE

LEAKS IN HYDRAULIC SYSTEMS CAN CAUSE SEVERE

INJURY. MOST DAMAGE OCCURS DURING THE FIRST

FEW HOURS. SEEK MEDICAL ATTENTION IMMEDIATELY.

SURGICAL REMOVAL OF OIL MAY BE NECESSARY.

USE ONLY BASTA APPROVED BIODEGRADABLE HYDRAULIC FLUID