Tech 500

User Guide rev1.0

JUNE 2013

22

TOOLKIT

Program Sensor

Access to program Aftermarket sensors. For more information, please log into the

tools.bartecusa.com account.

RKE Test

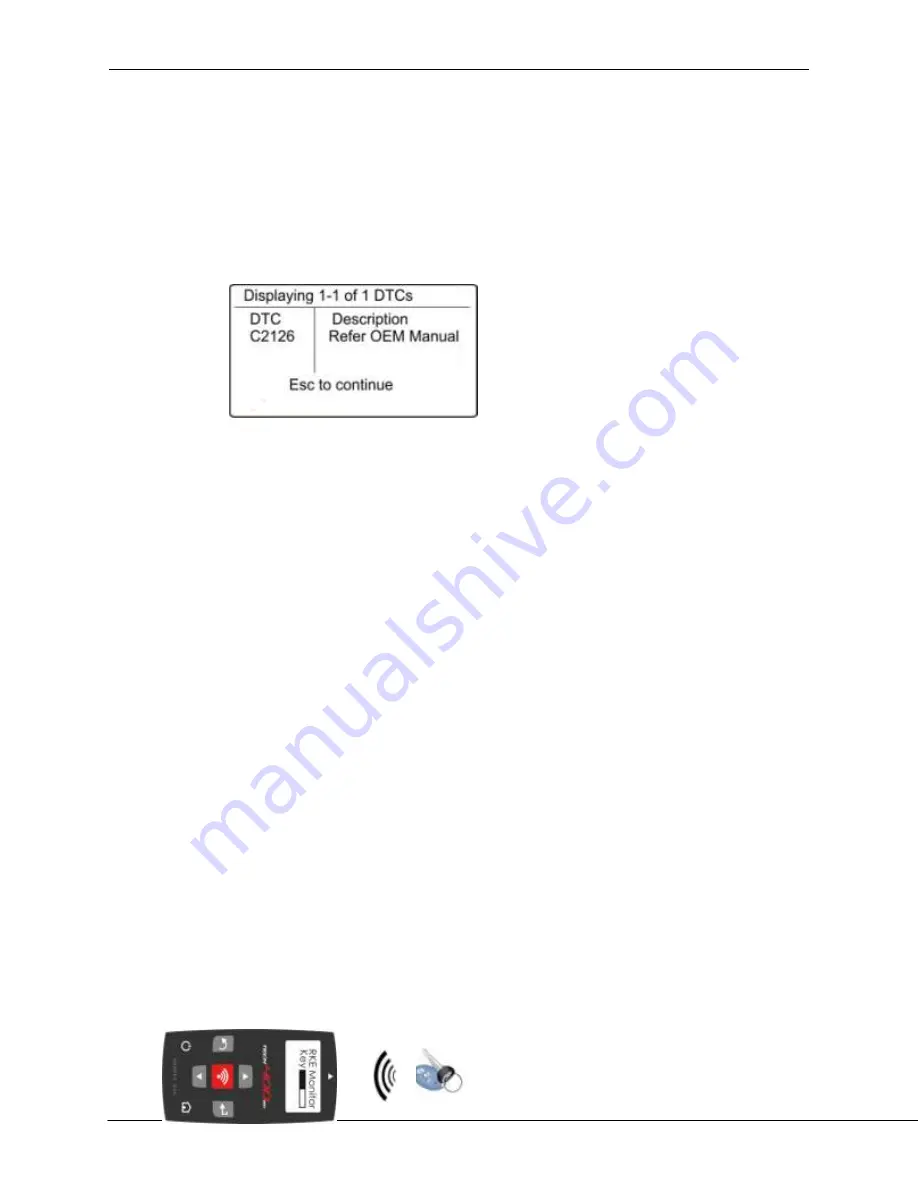

Once the Screen appears as below, hold the Key Fob as shown, and press the function buttons

on the FOB. The Tech500 will check only for a signal present. Verifying the Key Fob is

transmitting is important when performing relearn processes that use the Key Fob.