RDG603A23

–

Issue 20

Page 23 of 84

6. Pressurised Water Header Tank

WARNING:

SCALD HAZARD!

NEVER REMOVE THE HEADER TANK CAP IF THE ENGINE IS

HOT. STEAM AND HOT COOLANT MAY SPURT OUT AND CAUSE INJURY. TIGHTEN

THE HEADER TANK CAP SECURELY AFTER BEING REMOVED. STEAM CAN

SPURT OUT DURING ENGINE OPERATION IF THE CAP IS LOOSE.

•

The pressurised header tank should be mounted higher than the level of the engine,

no less than 300mm, and no more than 1m from the engine, to prevent cooling system

air locks.

•

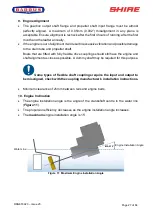

The header tank has two hose connections of different internal diameter’s

.

The smaller

internal diameter hosetail (left side of tank) should be connected to the top of the

engine. This is the air-bleed. The larger internal diameter hose-tail (right side of the

tank) should be connected to the lower pipe on the engine. This is the water-fill. The

hoses

MUST

be connected correctly.

Figure 7: Shire 90 Header Tank Connections

•

A constant rise on pipework is required to prevent air locks

7. Shaft Connection and Propeller Selection

•

Some type of flexible coupling must be used to connect the gearbox output flange to

the propeller shaft flange.

•

Please note, underperforming engines will not be covered under warranty if the cause

of the poor performance is found to be the use of an inappropriate propeller.