#0-313A-SBA (6/01)

Page 14 of 14 pages

BARRETT CENTRIFUGALS INC.

1-800-228-6442

The sensor must be secured to the motor housing by the jam nut.

The green LED on the sensor should be lit, indicating that it is receiving power.

To adjust the sensitivity turn the sensitivity adjustment potentiometer, with a screwdriver,

all the way in the clockwise direction.

With the machine’s lid open, manually spin the machine’s carrier. The yellow LED on the

sensor should blink, the more speed the more rapid the blinking.

When the yellow LED stops flashing the machine is ready to run a cycle.

A flashing output signal from the sensor is interpreted by the PLC as spindle rotation. If

the drive motor coil (1M) is energized and the PLC does not receive or loses the rotation

signal the machine will immediately brake to a stop. The red light on the machine’s push

button station will illuminate to indicate a system fault. The fault signal will only reset when

the machine’s disconnect is turned off.

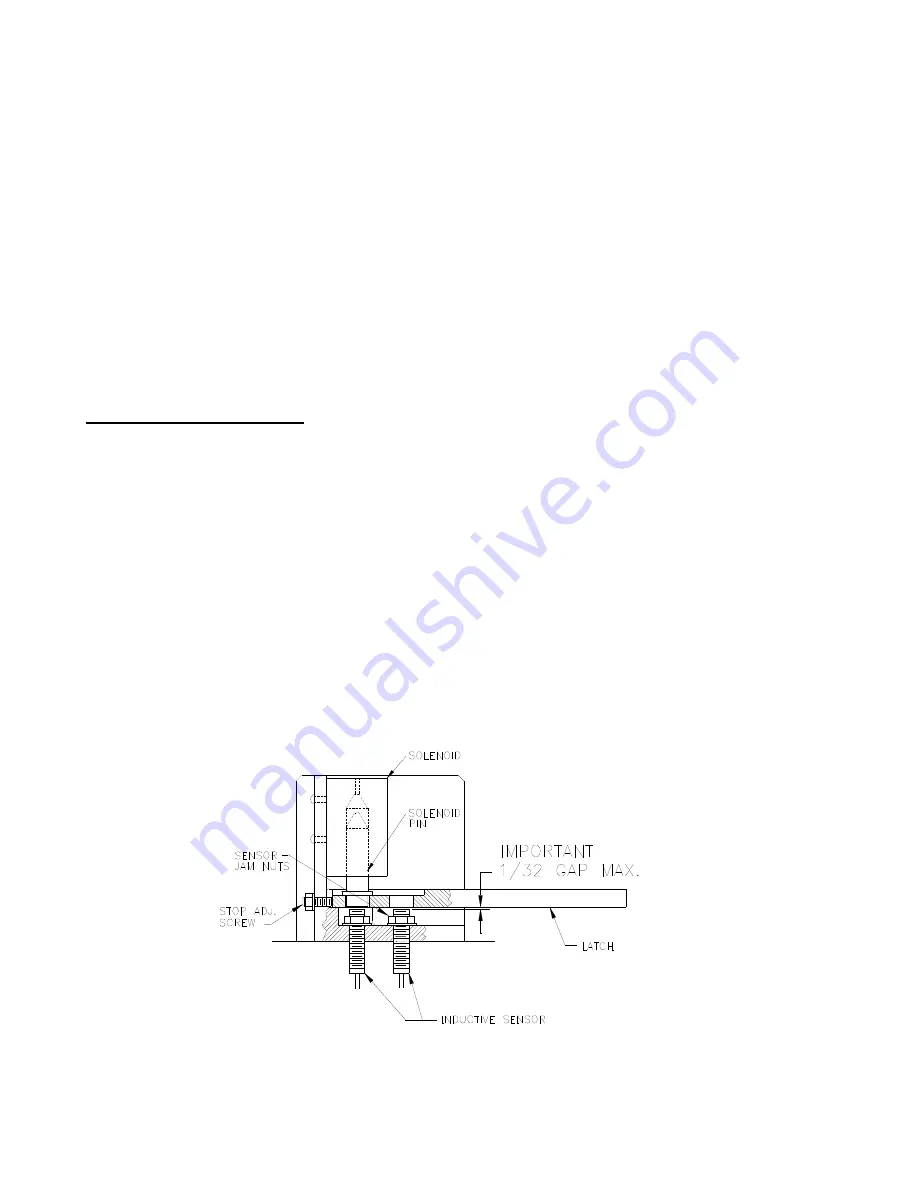

LID LATCH ADJUSTMENT (Ref. to Fig. 4)

Before any maintenance is performed on the lid latch be sure power is off and locked out. To

remove the sheet metal guard protecting the latch assembly, first remove the front cover of

the push button station enclosure. Remove the screws holding the guard in place and slide it

off of the assembly. Clean any contamination or build-up from all assembly components (use

compressed air if available). If necessary remove the solenoid pin and clean thoroughly. Be

sure the pin slides freely in the solenoid cylinder.

It is very important that the pin is

aligned properly when the solenoid is fastened to the bracket

.

While manually holding the pin

up

, slide the lever into its closed position and visually inspect

the gap between the sensor tips and the bottom surface of the latch. The gap should be

approximately 0.03 in. If not, loosen the sensor jam nuts and adjust the height by carefully

turning the sensor barrel. Be careful not to over extend the sensor tip as it could be damaged

if struck by the latch. If the sensor does not turn freely apply some WD-40 or similar lubricant

to the threads. When the sensors are adjusted properly, tighten the jam nuts to

approximately 48 inch pounds of torque.

Fig. 4.

Lid latch components