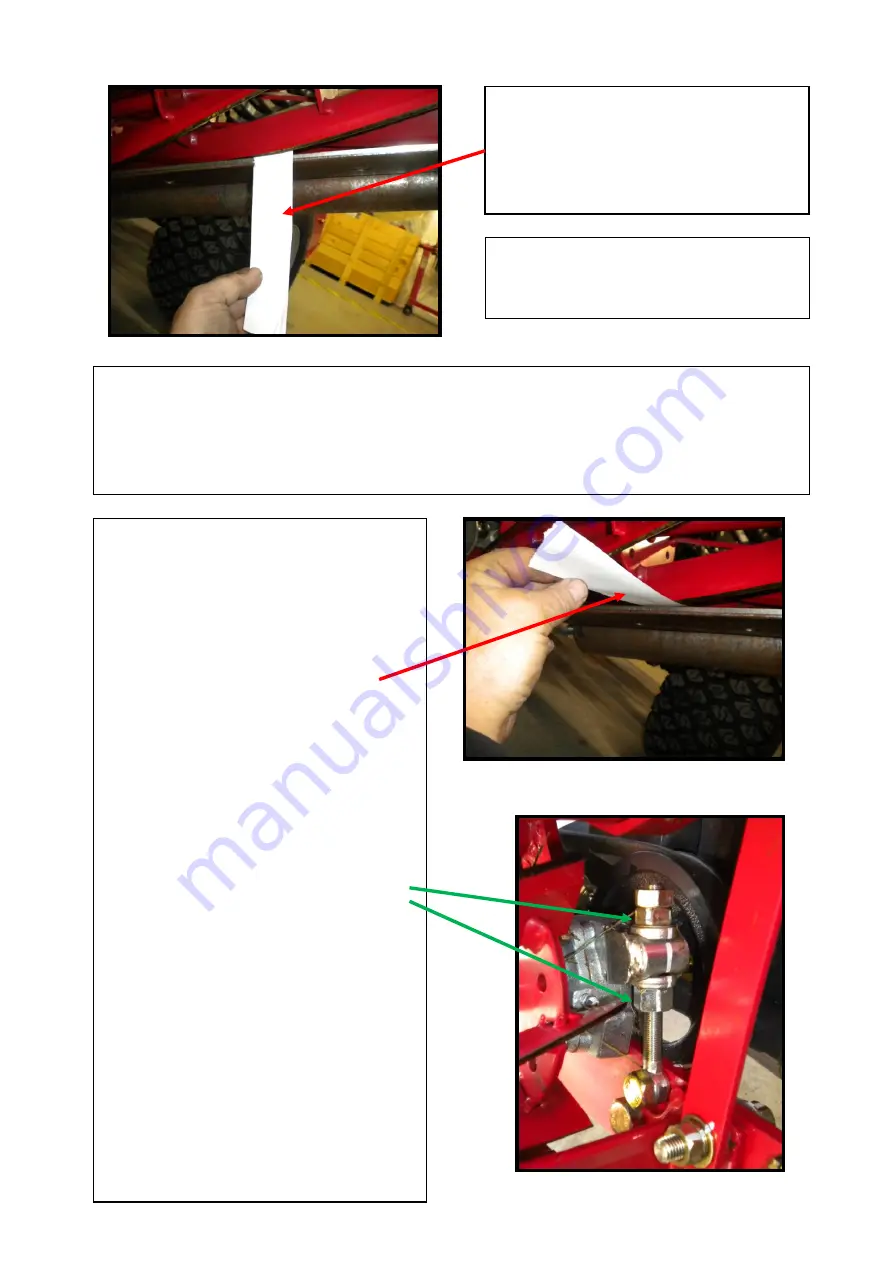

Check the cut again by using a strip of paper

as previously explained. Check both ends of

the blades and not just in the middle.

Once

again please remember to never put your

hand into the cutting cylinder.

If the paper is still not cut correctly, repeat

the blade lowering procedure as described

above.

If one end of the cutting cylinder cuts the paper but the other end does not, then only adjust the end

that is not cutting, but be aware that this could have an effect on the other end so always check both

ends with paper after making any adjustment.

Keep adjusting both ends until the paper is cut right across the length of the bottom blade.

Once the blades are cutting paper right across

the length of the bottom blade then you need

to check that you do not have excessive blade

contact.

To do this you need to use another strip of

paper but this time hold it flat along the

surface of the bottom blade.

When you rotate the cylinder the paper

should not be cut but should just leave an

indentation line. If it does this it is set ok. If it

cuts the paper then the contact is too great

and the blades will need adjusting to provide

slightly less contact. This is done by turning

the blade adjuster nuts anti-clockwise by a

very small amount in order to increase the

gap slightly.

Only adjust the side which is too tight. If both

sides are too tight then adjust them both but

remember to only use very small adjustments

and keep checking both sides.

The blades are correctly adjusted when both

sides cut paper when it is held square to the

bottom blade but only leaves an indentation

in the paper when it is held flat along the

bottom blade.