-25-

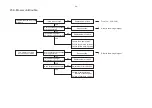

16-3. Confirmation after adjustment

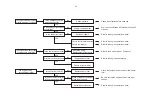

18-1. Hoisting

Stop the engine and move the respective levers to check for interference.

Check that the machine is in the neutral position and will not move even if the

engine is in the full-throttle state.

(When the side brake lever is pulled and returned)

After moving the traveling lever to move the machine, release the traveling lever,

and check that the machine will not move.

After the above-mentioned adjustment, confirm the following:

17. Engine

(JIS No.2 diesel oil)

a) Use the low sulfur or ultra low sulfur diesel fuel (JIS No.2 diesel).

b) The machine is to be operated under severe condition such as vibration, slopes,

and dust. Change the entire engine oil 10 hours after the initial operation. Then

while continuing inspection and replenishment before use, change the entire

quantity every 100 hours thereafter.

Change all the oil filters simultaneously as well.

When using the machine in a dusty place, change oil and the oil filters more

frequency.

The quantity of the engine oil is 5.5 liters. Use the diesel engine oil in the service

class CD or above specified by the API standard.

c) When air is sucked in the fuel system of a diesel engine, the engine will not be

started. Inspect and maintain the diesel engine at all times to prevent entry

of air into the fuel system. Operation will be difficult when the fuel filter and

electromagnetic pump filter are clogged with dust or when water remains in them.

Drain water or clean filters every 50 hours. Replace filters with new ones every

200 hours.

d) Keep a pre-cleaner attached to the suction port of the air cleaner at all times

during operation. Be sure to clean the dust cup before operation.

e) Mix antiseptics (long-life coolant) into water, and put the mixture in the reserve

tank up to the MAX position as a radiator cooling water. Change the cooling water

every 50 hours. Check and supply the cooling water before operation. When the

temperature is likely to drop below the freezing point, use an antifreeze mixture.

When the radiator fins are clogged with dust, blow air to clean them.

Refer to the diesel engine operation manual for the method of handling

the engine.

There is a risk of a skin burn. Do not open the radiator cap during or right after

operation.

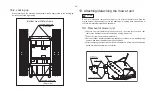

18. Hoisting and jacking up the machine

Precautions as to hoisting

a) Qualification necessary to use a crane to hoist the machine

For hoisting the machine, follow the appropriate laws of the country where it is

hoisted.

b) Hoisting procedure

Lower the mower portion until it touches the ground.

Pull out the four hoisting hooks and secure them with pins. Hook the wire ropes

completely with shackles. Use wire ropes with sufficient strength. Be sure to

use four ropes of 2.5 m or more in length.

Pay attention to the position of the center of gravity during hoisting to balance

the machine sufficiently. Do not approach the machine inadvertently during

hoisting.

CAUTION

CAUTION

CAUTION

1

2

3

1

2

3

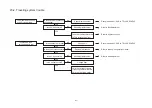

When lowering the machine, keep the machine horizontally and lower it in a

manner that the crawlers at right and left will touch the ground at the same time.

Impact applied to the traveling motor (sprocket) at that time will cause failure.

4

Precautions as to handling of engine