-21-

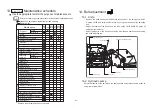

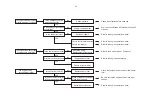

13. Maintenance schedule

Refer to the diesel engine operation manual for the method of handling the engine.

Inspection, adjustment, replenishment and cleaning

Replacement

Engine

Main unit

Knife section

Others

Maintenance

Engine oil

Oil filter

Fuel filter

Electromagnetic pump filter

Air cleaner element

Precleaner

Cooling water (qty, leakage, etc.)

Fuel (qty, leakage, etc.)

Hydraulic oil (qty, leakage, etc.)

Hydraulic oil filter

Tightening of hydraulic hose/joint

Electrolyte

Radiator core

Side brake

Traveling lever

Neutral position

Emergency switch operation

Step operation

Operation of respective switches and meters

Lighting of pilot lamp

Knife tension operation

Strength of knife tension

V-belt tension

Crawler tension

Breakage of hammer knife

Looseness of knife mounting bolt

Knife shaft bearing

Dust-proof cover and protection plate

Greasing each section

Looseness of screw in each section

Accumulation of dust

Visible damage

Initial

After 10 hr

Hydraulic

motor oil

Initial

After 50 hr

Before

use 10hrs

every

50hrs

every

100hrs

every

200hrs

every

500hrs

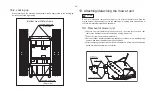

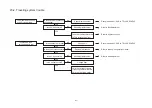

14-1. Knife

14. Belt adjustment

Remove the knife shaft cover and adjust the tension of the belt put on the B3

V-pulley 30150 and knife shaft V-pulley by using the tension pulley adjusting

bolt.

Adjust the tension of the belt put on the B3 V-pulley 30175 and B6 V-pulley by

using the lever adjuster.

Adjust the tension of the belt put on the B6 V-pulley and engine pulley by using

the knife adjusting rod.

Knife adjusting rod

Lever adjuster

Tension pulley adjusting bolt

Knife shaft V-pulley

B3 V-pulley

B6 V-pulley

Engine pulley

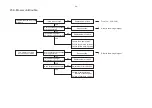

14-2. Hydraulic pump

Adjust the tension of the belt put on the engine pulley and hydraulic pump pulley by

using the lever adjuster.

*

Replace the hydraulic hoses every 4 years.

C A U T I O N

Use the appropriate tools for the purpose of maintenance etc.