4

Recommendations & Warnings

4

Receiving inspection

Upon receiving the pump, it should

be inspected for damage or

shortages. If damage has occurred,

file a claim immediately with the

company that delivered the pump. If

the manual is removed from the

packaging, do not lose or misplace.

4

Storage

Any product that is stored for a

period longer than six (6) months

from the date of purchase should be

bench tested prior to installation. A

bench test consists of, checking the

impeller to assure it is free turning

and a run test to assure the motor

(and switch if provided) operate

properly.

4

Service Stations

To find the nearest Barmesa Pumps

authorized service shop, please

directly contact your distributor or

the factory.

The anchors of the motor are to be

anchor,

on

a

raised

base,

approximately 4", this to prevent

accumulated water from entering the

motor.

**See friction table in pipes and fittings

to determine the dimensions of the

suction and discharge. (Page 8)

At any time exceeding six (6) months,

but no more than twenty four (24),

the equipment must be stored in a

controlled area, keeping it away from

contact with rain, dust, etc., and the

temperature is maintained between

43-104 °F. If there is a possibility of

high humidity (coastlines, etc.), the

entire unit must be sprayed with

antioxidant liquid.

4

Installation

The pump should be as close as

possible to the liquid to be pumped,

with a minimum number of

couplings, adapters, etc., in order to

reduce friction on the suction side.

The suction and discharge piping

must be perfectly aligned in the

pump

volute

and

supported

independently using support or

anchors, this to prevent excessive

load on the volute.

A successful operation depends on

the calculation of the friction loss in

the suction, considering acceptable

limits. The minimum suction pipe size

to use can be determined by

comparing the NPSH available at the

pump suction against the NPSH

required by the impeller, as shown in

the performance curves.

Usually, we recommend using a pipe

diameter of 1/2" to 1" greater as that

of the suction volute or body.

A strainer or sieve should be installed

in the suction to prevent the entry of

objects. The strainer must have a free

entry area at least three times the

pipe diameter. Usually a suction valve

is combined with a strainer

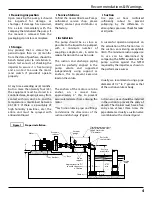

Figure 1

.

Use pipe or hose reinforced

sufficiently

robust

to

prevent

collapsing by the difference in

atmospheric pressure. Check for leaks

at all joints.

4

Suction

Figure 1

Proper installation.

Motor

Anchors

Base

Pippe

support

Eccentric

reducer

Vacuum

gauge

Straight pipping as short

as possible, but not less

than 6 times the

"D" diameter

Perfectly

sealed joints

As close

as possible

As close

as possible

Strainer

Appropriate size "D"

to avoid the excess

of friction

1 "D"

min.

4 "D"

min.

Suction

valve

Suction

valve

4"

"D"

barmesa.com

Summary of Contents for IB Series

Page 15: ...14 barmesa com...