5

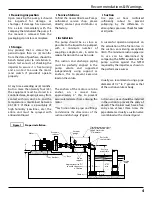

Figure 2

Wrong installation.

Without

strainer

Vortex

"D"

Too much

height

Less than

4 "D"

Long piping

Concentric

reducer

Air

Air leaks

A valve in the suction pipe

is not recommended

Piping elbow immediately

installed after the suction

Installation

Suction height

- suction pipe should

have a slope of 0.39" per 3.3 ft of

suction. Never exceed 16.4 ft suction,

considering friction.

(Figure 3)

Positive/Drowned Suction

- A gate

valve is installed in the suction pipe

to service the pump

(Figure 4)

. Volute

or body have plugs, and these must

be removed to allow trapped air to

escape.

Use

pipe

or

hose

reinforced

sufficiently

robust

to

prevent

destruction due to high pressure.

4

Discharge pipe

Due to the cost of energy or BHP

necessary to overcome the friction

generated by using a smaller

diameter pipe, a larger diameter

discharge pipe is commonly used

than the required by the volute or

body.

Figure 3

Inclination.

Correct

0.39" of inclination

per 3.28 ft

Incorrect

Air pocket

Figure 4

Positive suction.

Check valve

(completely open)

"D"

6 "D" min.

Pressurized water

Correct

Figure 5

Positive suction.

A retention valve in the suction pipe

is not recommended. If required,

better install the valve in the

discharge pipe.

Valve partially

closed

Incorrect

barmesa.com

Summary of Contents for IB Series

Page 15: ...14 barmesa com...