Starting

When starting for the first time your

equipment check that the discharge

valve is 90% closed. Gradually open

the valve until the motor runs at full

load (amperage plate). Never allow

the amperage consumed by the

pump exceeds the maximum

permitted by the engine.

Mechanical Seal -

To inspect or

replace the shaft seal, remove the

body and impeller. If any part shows

wear or damage, replace both parts

(stationary seat and rotary part). The

rotating seal parts may be stuck

together with the shaft, this happens

when the seal has been assembled

for a long time.

If the mechanical seal does not leak

and there is need to open the pump

for inspection or cleaning,

DO NOT

remove the seal, remove the spring

only if the impeller needs to be

removed. Once a seal has been in

operation is very difficult to remove

and reassembly without creating a

seal leak.

IMPORTANT!

-

Always

unplug the pump before

applying

maintenance,

service or repair to avoid

electric shock.

Handle seal parts with

extreme care. DO NOT

damage lapped surfaces.

08

Operation & Maintenance

Mechanical seal

Mechanical seals installed in this

pumps are lubricated by water,

therefore the pump should not be

operated dry. You will find the

appropriate seal for each use and

liquid to be pumped, check with your

Barmesa Pumps distributor for more

information.

Stuffing box*

If the pump has graphite packing

(stuffing box) consider the following:

Ÿ

When the pump is placed into

operation, the liquid will drip from

the stuffing box; if this does not

happen, loosen the nuts on the

stuffing box until dripping occurs.

Ÿ

Once the pump has operated for a

reasonable period and the

dripping has not decreased to “a

few drops per minute", it is

necessary to tighten the nuts

stuffing box. If tightening the nuts

the required drip is not achieved,

the graphite packing rings must be

replaced.

Ÿ

After a few minutes of operation,

gradually tighten the nuts until the

dripping decreases but not cease.

Frame*

All pumps come with factory

lubricated bearings. It is very

important to have oil in the oil tank.

(Use oil DTE26). Change the oil every

1,000 hours of operation, considering

a daily operation of 8 hours.

It is important not to overfill the oil

tank because it would cause an

increase in pressure by heating,

affecting the bearings and seals. In

normal

operation,

the

frame

temperature increases 122 °F above

ambient temperature.

*For Barmesa pumps with universal

transmission.

Flexible coupling*

All pumps operated through flexible

coupling or by pulleys and belts must

be perfectly aligned to ensure

smooth operation. In no case

problems

occur

with

flexible

couplings if the pump-motor

alignment is correct. All pumps are

manufactured

following

this

condition.

Maintenance

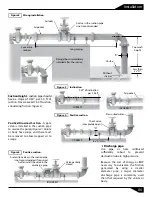

Body and Impeller -

All pump parts

are removable by removing nuts and

bolts. For body maintenance,

disconnect

the

suction

and

discharge, and remove the body of

the intermediate coupling. For

maintenance of the impeller is not

necessary to remove the suction or

discharge, simply remove the body

nuts; this would uncover the impeller.

Examine and replace if it shows wear

or damage.

When

the

impeller

requires

replacement, remove the screw of

the shaft, and using a puller, remove

the impeller being careful not to

abuse the keyway of the shaft.

Disassembly

Mechanical Seal -

Perform the steps

above. Remove the rotating part. It

may be necessary to remove the

intermediate link to remove the

stationary seat. To do this, remove the

nuts and washers that attach the

coupling to the motor. When

removing the coupling, the steady

part will move towards the front seat

of the shaft and the sleeve. If the seat

does not yield itself, push from the

rear of the coupling.

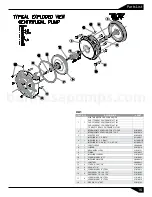

Reassembly

Mechanical Seal -

Identify all parts of

Figures 7 and 8. The ring (6) and seat

(1) are perfectly polished, so care

must be taken not to scratch or

smudge. The cleaning during the

assembly process is very important.

IMPORTANT! - All parts

must be clean before

reassembly.

barmesapumps.com