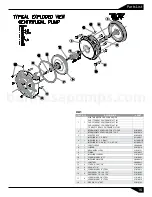

Parts List

IA3

IA3H

ITEM QTY.

DESCRIPTION

# PART

ELECTRIC MOTOR, 200-230/460, ODP

3 HP, 1740 RPM, 3 PH, FRAME 182T JM

5 HP, 1730 RPM, 3 PH, FRAME 184T JM

7.5 HP, 1750 RPM, 3 PH, FRAME 213T JM

15 HP, 3530 RPM, 3 PH, FRAME 254T JM

20 HP, 3525 RPM, 3 PH, FRAME 256T JM

25 HP, 3525 RPM, 3 PH, FRAME 284T JM

30 HP, 3525 RPM, 3 PH, FRAME 286T JM

40 HP, 3530 RPM, 3 PH, FRAME 324T JM

50 HP, 3530 RPM, 3 PH, FRAME 326T JM

INTERMEDIATE COUPLING, FOR 3 TO 5 HP, 1750 RPM

03010028

INTERMEDIATE COUPLING, FOR 7.5 HP, 3500 RPM

03010018

INTERMEDIATE COUPLING, FOR 15 & 20 HP, 3500 RPM

03010051

INTERMEDIATE COUPLING, FOR 25 TO 50 HP, 3525 RPM

03010020

3

1

VOLUTE CASE

03090042

IMPELLER IA3 FOR 3 HP, Ø7.50" (SHAFT Ø7/8")

03140035I

IMPELLER IA3 FOR 5 HP, Ø8.40" (SHAFT Ø7/8")

03140035J

IMPELLER IA3 FOR 7.5 HP, Ø9.00" (SHAFT Ø7/8")

03140035H

IMPELLER IA3 FOR 15 & 20 HP, Ø6.94" (SHAFT Ø1¼")

03140035B

IMPELLER IA3 FOR 25 HP, Ø7.50" (SHAFT Ø1¼")

03140035C

IMPELLER IA3 FOR 30 HP, Ø8.00" (SHAFT Ø1¼")

03140035D

IMPELLER IA3 FOR 40 HP, Ø8.75" (SHAFT Ø1¼")

03140035E

IMPELLER IA3 FOR 50 HP, Ø9.00" (SHAFT Ø1¼")

03140035F

SHAFT SLEEVE, FOR 3 TO 7.5 HP

30400808

SHAFT SLEEVE, FOR 15 TO 50 HP

30400812

SLINGER, FOR 3 TO 7.5 HP, Ø1¼"

92010014

SLINGER, FOR 15 TO 50 HP, Ø1¾"

92010016

MECH. SEAL, FOR 3 TO 7.5 HP

31030131

MECH. SEAL, FOR 15 TO 50 HP

31030133

8

1

O-RING

92010033

IMPELLER'S SCREW, FOR 3 TO 7.5 HP

91010345C

IMPELLER'S SCREW, FOR 15 TO 50 HP

91010351

LOCK WASHER, 3/8" SS, FOR 3 TO 7.5 HP

91010061

LOCK WASHER, 1/2" SS, FOR 15 TO 50 HP

91010062

IMPELLER WASHER, FOR 3 TO 7.5 HP

30400418

IMPELLER WASHER, FOR 15 TO 50 HP

30400416

SHAFT KEY, FOR 3 HP TO 7.5 HP

30400631

SHAFT KEY, FOR 15 TO 50 HP

30400633

13

8

STUD 3/8-16X 1.50"

91010303

14

8

HEX NUT 3/8"

91010413

15

8

LOCK WASHER 3/8"

91010012

CAP SCREW, 3/8-16 X 1.25" FOR 3 & 5 HP

91010243

CAP SCREW, 1/2-13 X 1.50" FOR 7.5 TO 20 HP

91010263

CAP SCREW, 5/8-11 X 1.50" FOR 25 TO 50 HP

91010282

LOCK WASHER, 3/8" STEEL, FOR 3 & 5 HP

91010012

LOCK WASHER, 1/2" STEEL, FOR 7.5 TO 20 HP

91010014

LOCK WASHER, 5/8" STEEL, FOR 25 & 50 HP

91010015

18

1

PIPE PLUG 1/2" NPT

93010142

19

3

PIPE PLUG 1/4" NPT

93010143

17

4

9

1

10

1

11

1

12

1

16

4

2

1

4

1

5

1

6

1

7

1

1

1

ITEM QTY.

DESCRIPTION

# PART

ELECTRIC MOTOR, 200-230/460, ODP

30 HP, 3525 RPM, 3 PH, FRAME 286T JM

40 HP, 3530 RPM, 3 PH, FRAME 324T JM

50 HP, 3530 RPM, 3 PH, FRAME 326T JM

60 HP, 3565 RPM, 3 PH, FRAME 364T JM

75 HP, 3565 RPM, 3 PH, FRAME 365T JM

2

1

INTERMEDIATE COUPLING, FOR 30 TO 75 HP, 3500 RPM

03010020

3

1

VOLUTE CASE

03090042

IMPELLER IA3H FOR 30 HP, Ø7.50" (SHAFT Ø1¼")

03140066B

IMPELLER IA3H FOR 40 HP, Ø7.94" (SHAFT Ø1¼")

03140066C

IMPELLER IA3H FOR 50 HP, Ø8.50" (SHAFT Ø1¼")

03140066D

IMPELLER IA3H FOR 60 TO 75 HP, Ø9.0" (SHAFT Ø1¼")

03140066E

5

1

SHAFT SLEEVE, FOR 30 TO 75 HP

30400812

6

1

SLINGER, FOR 30 TO 75 HP, Ø1¾"

92010016

7

1

MECH. SEAL, FOR 30 TO 75 HP

31030133

8

1

O-RING

92010033

9

1

IMPELLER'S SCREW

91010351

10

1

LOCK WASHER, 1/2" SS

91010062

11

1

IMPELLER WASHER

30400416

12

1

SHAFT KEY, FOR 30 TO 75 HP

30400633

13

8

STUD 3/8-16X 1.50"

91010303

14

8

HEX NUT 3/8"

91010413

15

8

LOCK WASHER 3/8"

91010012

16

4

CAP SCREW, 5/8-11 X 1.50"

91010282

17

4

LOCK WASHER, 5/8" STEEL

91010015

18

1

PIPE PLUG 1/2" NPT

93010142

19

3

PIPE PLUG 1/4" NPT

93010143

1

1

4

1

19

barmesapumps.com