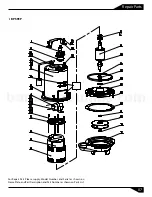

08

Parts List

BPSTEP

For Repair Part Please supply: Model Number and Serial as shown on

Name Plate, and Part Description and Part Number as shown on Parts List.

barmesapumps.com

ITEM

DESCRIPTION

QTY

MATERIAL

1

Cable Assembly

20 ft

SOW

2

O-ring Ø4.5" x 3.1"

1

NBR40

3

Pump body

1

HT200

4

Capacitor 25uf/370V 90 °C

1

Aluminium

5

Upper bearing plate

1

ZL102

6

Bearing 6203

2

7

Wave washer 39

1

65Mn

8

Temperature protector

1

9

Stator

1

10 Rotor component

1

11 Stator component

1

12 Hex head bolt 5/16"

4

304

13 Spring washer

8

304

14 Lower bearing plate O-ring

1

NBR40

15 Lower bearing plate

1

HT200

16 Impeller Ø117.3

1

Polypropylene

17 Casing

1

HT200

18 "U" shpe ring Ø31.5 x Ø44.3 x 6.5

1

NBR40

19 Casing sealing washer

1

Rubber

20 Hex socket cap screws 1/4" - 20UNCx28

2

304

21 "V" shape ring

1

NBR40

22 Mechanical seal Ø31.8 x Ø15.9 x 32.5

1

SiC/SiC

23 Elastic collar 40

1

65Mn

24 Elastic collar 17

2

65Mn

25 Lengthern bolt #8-32 x 140

4

Q235A

26 Flat washer 4

4

Q235A

27 Spring washer 4

4

65Mn

28 Capacitor clamp

1

08F

29 Cross recessed pan head screw M4x8

2

Q235A

30 Ground lead

1

31 Hex bolt 5/16" - 18UNCx25

4

304

32 Hex socket pipe stopper 3/8" - 18 NPT

1

304

33 Handle

1

304

34 Name plate

1

304

35 Nail for name plate 2x4

4

Cu

36 Float switch (optional)

1

37 Clamp (optional)

1

2Cr13+NBR40

38 Cross recess pan head screw #10-32UNFx12 (optional)

1

304

39 Trademark signs

1

304