Pressure Test (If oil has been

drained) -

Remove pipe plug from

housing. Apply pipe sealant to

pressure gauge assembly and tighten

into hole. Pressurize motor housing

to 10 PSI. Use soap solution around

the sealed areas and inspect joints

for "air bubbles".

After leak is repaired, dispose of old

oil properly, and re ill with new oil.

f

Oil Replacement -

Set unit upright

and refill with new cooling oil as per

table below . Fill to just above motor,

but below capacitor as an air space

must remain in the top of the housing

to compensate for oil expansion.

Apply pipe thread compound to

threads of pipe plug then assemble

to housing.

Oil Testing

Ÿ

Drain oil into a clean, dry container

by placing pump on it’s side,

remove pipe plug (20), from

housing (10).

Ÿ

Check oil for contamination using

an oil tester with a range to 30

kV

breakdown.

Ÿ

If oil is found to be clean and

uncontaminated

(measuring

above 15 V breakdown), re ill the

k

f

housing.

Ÿ

If oil is found to be dirty or

contaminated (or measures below

15 breakdown), the pump must

kV

be carefully inspected for leaks at

the shaft seal, conduit box, o-rings,

pipe plug and pressure valve,

before re illing with oil. To locate

f

the leak, perform a pressure test.

Pressure builds up extremely

fast, increase pressure by

"TAPPING" air nozzle. Too

much pressure will damage

seal.

DO NOT exceed 10 PSI.

Pressure Test (If oil has NOT been

drained) -

Oil should be at normal

level. Remove pipe plug from

housing. Apply pipe sealant to

pressure gauge assembly and tighten

into hole. Pressurize motor housing to

10 PSI. Use soap solution around the

sealed areas above the oil level and

inspect joints for "air bubbles". For

sealed areas below oil level, leeks will

seep oil. If, after five minutes, the

pressure is still holding constant, and

no "bubbles"/oil seepage is observed,

slowly bleed the pressure and remove

the gauge assembly. Replace oil. Leek

must be located and repaired if

pressure does not hold.

DO

NOT

overfill

oil.

Overfilling of housing with oil

can create excessive and

dangerous hydraulic pressure

which can destroy the pump

and create a hazard.

Overfilling oil voids warranty.

05

Service

Cooling Oil

Recommended Supplier/Grade

BP

Enerpar SE100

Conoco

Pale Parafin 22

Mobile

D.T.E. Oil Light

Shell Canada

Transformer-10

Texaco

Diala-Oil-AX

Cooling Oil -

Anytime the pump is

removed from operation, the cooling

oil in the motor housing should be

checked visually for oil level and

contamination. To check oil, set unit

upright. Remove pipe plug from

housing. With a flashlight, visually

inspect the oil in the housing to make

sure it is clean and clear, light amber

in color and free from suspended

particles. Milky white oil indicates the

presence of water. Oil level should be

just above the motor when pump is

in vertical position.

Servicing

If, after five minutes, the pressure is

still holding constant, and no

"bubbles" are observed, slowly bleed

the pressure and remove the gauge

assembly. Replace oil. Leek must be

located and repaired if pressure does

not hold.

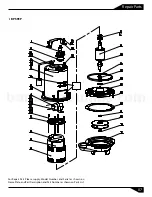

Disassembly & Assembly

Impeller U-cup, V-ring and Volute:

Disconnect power. Remove cap

screws and lock washers vertically lift

motor, housing and seal plate

assembly from volute. Clean out

volute if necessary. Inspect gasket

and replace if cut or damaged. Check

U-cup for damage. If replacement is

needed, cut the U-cup from the

volute and clean surface of bore.

Clean and examine impeller, for

cracks or breakage and replace if

required. To remove impeller, place a

flat screwdriver in the slot of the end

of the shaft to hold the shaft

stationary while unscrewing the

impeller.

barmesapumps.com