Service Manual

Last Updated - 9/28/2016

495B SE (S)

66

1. Remove the hex lock nuts and washers at the top of the brush holding stud along with the outboard bearing, if

used. This will allow the brush assemblies to be removed. NOTE: Some smaller collectors use cap screws or

may be equipped with socket screw-type set collars instead of hex nuts.

2. Carefully remove the brushes without over-stretching the brush springs and arrange in order of removal with the

spacers.

3. Replace the damaged brush assembly and then reassemble the brushes and spacers in reverse of the removal

order. This will ensure the correct spacing between electrically live parts, which is critical on higher voltages of

110VAC or more.

4. Be sure that all brushes are snapped in tight and making full contact with their corresponding brass ring.

5. Check that all springs are hooked correctly through the brush arm.

NOTE: Special care should be used when handling or replacing the 7.5 amp brush/arm/spring assemblies. Because

of their small size, they can be broken if forced up or down. In the correctly installed position, the possibility of

breakage is minimal.

LUBRICATION

Electric collectors with spun aluminum covers can be mounted either upright or inverted.

UNITS MOUNTED IN STANDARD UPRIGHT POSITION:

Units mounted upright (with the cover on top, as shown in illustration) have a nylon bearing in the base, eliminating

the need for lubrication.

UNITS MOUNTED IN THE INVERTED POSITION:

Units mounted in the inverted position have a grease seal and a shortened nylon bearing in the base (not shown),

which keeps most contaminants and fluids from running down the mounting tube into the collector assembly. A liquid-

tight connector for the brush harness exit is also supplied in the base of a collector to be used in the inverted position.

NOTE: Previous to 1987, some electrical collectors supplied for inverted mounting were equipped with bases

containing o-rings rather than a nylon bearing.

Lubricate the seal (or o-ring) with GE G322L Versi-lube or equivalent silicone grease before insertion of the mounting

tube.

ELECTRIC COLLECTOR MAINTENANCE CONTINUED...

Summary of Contents for 495B - SE

Page 3: ...Introduction...

Page 15: ...Maintenance...

Page 18: ...Service Manual Last Updated 9 28 2016 495B SE S 18 SERVICE SCHEDULE...

Page 19: ...Service Manual 495B SE S 19 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 20: ...Service Manual Last Updated 9 28 2016 495B SE S 20 SERVICE SCHEDULE CONTINUED...

Page 21: ...Service Manual 495B SE S 21 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 22: ...Service Manual Last Updated 9 28 2016 495B SE S 22 SERVICE SCHEDULE CONTINUED...

Page 28: ...Hydraulic...

Page 29: ...Service Manual 495B SE S 29 Last Updated 9 28 2016 HYDRAULIC DRAWING 603 01594...

Page 30: ...Service Manual Last Updated 9 28 2016 495B SE S 30 HYDRAULIC SERVO DRAWING 603 01593...

Page 31: ...Service Manual 495B SE S 31 Last Updated 9 28 2016 HYDRAULIC SCHEMATIC 607 00185...

Page 32: ...Service Manual Last Updated 9 28 2016 495B SE S 32 HYDRAULIC DRAWING TANDEM 603 01574...

Page 33: ...Service Manual 495B SE S 33 Last Updated 9 28 2016 HYDRAULIC SERVO TANDEM 603 01573...

Page 34: ...Service Manual Last Updated 9 28 2016 495B SE S 34 HYDRAULIC SCHEMATIC TANDEM 607 00184...

Page 56: ...Electrical...

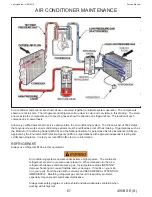

Page 71: ...Service Manual 495B SE S 71 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 72: ...Service Manual Last Updated 9 28 2016 495B SE S 72 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 73: ...Service Manual 495B SE S 73 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 74: ...Service Manual Last Updated 9 28 2016 495B SE S 74 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 78: ...Maintenance...

Page 88: ...Structural...

Page 93: ...Trouble Shooting...