page 74

595 ML CRL (S)

800-00177

AIR CLEANERS WITH VACUATOR VALVE

On vacuator valve equipped models, (see figure 3)

dust cup service is cut to a minimum. A quick check

to see that the vacuator valve is not inverted,

damaged, or plugged is all that is necessary.

DUST CUP

VACUATOR VALVE

Figure 3

CHECKING AIR CLEANER RESTRICTION

Check the Air Cleaner Restriction Indicator daily for restriction. Restriction is caused by dust and dirt

accumulating on the Air Cleaner Element. The method used to check the restriction will depend upon the type of Air

Cleaner on the machine.

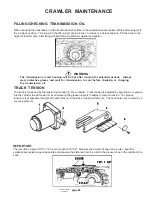

AIR CLEANERS WITH RESTRICTION INDICATORS

These air cleaners have a restriction indicator mounted to the Air

Cleaner body (see Figure 4). The indicator plunger will be in the

green zone when the Air Cleaner is empty - and will move up

towards the red zone when the Air Cleaner is full of dust and dirt.

When in the red zone, this means the Air Cleaner element needs to

be replaced. See Replacing The Air Cleaner Element later on.

Figure 4

AIR CLEANERS WITHOUT RESTRICTION INDICATORS:

Measure the restriction of the Air Cleaner with a service gauge, or a water manometer at the restriction tap provided in

the Air Cleaner, the transfer pipe, or the blower intake. Replace the element only when the restriction has reached the

maximum allowed by the engine manufacturer. Contact the Barko Service Department for maximum values and any

other questions concerning this method.

CAUTION

Check the Air Cleaner Assembly daily for cracks,

loose clamps, or any other damage. If debris is able

to bypass the Air Cleaner for any reason, it can

damage the engine.

REPLACING THE AIR CLEANER ELEMENT

For minimum vehicle downtime, replace dirty air cleaner element with a new element. DO NOT TRY TO CLEAN THE

ELEMENT! Do not leave air cleaner open to the environment longer than it takes to remove element, inspect and

clean inside of air cleaner body, and install a new element.

When restriction indicates that element servicing is required, see the replacement steps on the next page.

SAFETY ELEMENT SERVICE (IF APPLICABLE)

The safety element is not intended to be cleaned.

For maximum engine protection and air cleaner service life, replace the safety element with a new safety element

every third primary element change.

RESTRICTION

INDICATOR

AIR CLEANER MAINTENANCE CONTINUED...

Summary of Contents for 595ML

Page 3: ...page3 595 ML CRL S 800 00177 Introduction Marker...

Page 16: ...page16 595 ML CRL S 800 00177 Maintenance A PREVENTIVE MAINTENANCE Maintenance...

Page 27: ...page27 595 ML CRL S 800 00177 Maintenance B HYDRAULIC SYSTEM...

Page 33: ...page33 595 ML CRL S 800 00177 HYDRAULIC PRESSURE ADJUSTMENT CONTINUED 558 01699...

Page 44: ...page44 595 ML CRL S 800 00177 Maintenance C ELECTRICAL SYSTEM MAINTENANCE...

Page 67: ...page67 595 ML CRL S 800 00177 Maintenance D POWER UNIT MAINTENANCE...

Page 77: ...page77 595 ML CRL S 800 00177 Structural E STRUCTURAL MAINTENANCE...

Page 84: ...page84 595 ML CRL S 800 00177 Trouble Shooting Marker Marker Marker...