24

17

Air

24

Air

2

Counterhold!

9

14

35

34

7

8

6

157

156

120

138

1

33

14

28

Air

24

Air

2

Counterhold!

9

14

35

34

7

8

6

157

156

120

138

1

33

14

28

33

1

24

(GB-IST-BBZO-0413) 21/24

The Company BARDIANI VALVOLE reserves the right to modify its products at any time without prior notice.

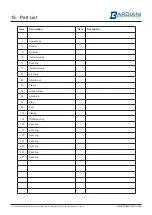

14. Assembly of BBZOG / BBZOH

9.

Assemble body (1) and as-

sembly (35) with clamp (33).

10.

Release air pressure to air fitting (24) and remo

-

ve 2 M6x10 to allow assembly of the

Giotto-Top

®

.

Air

8.

Supply air to

fitting (24).