Manual 2100-365

Page 24

23. MEASURING AIR TEMPERATURE

RISE

Air temperature rise (supply air temperature minus

return air temperature) must be within allowable air

temperature rise range specified on furnace rating

plate and in Table 1.

You will need 2 thermometers with 1 degree

resolution capable of reading up to 200 degrees F.

Check thermometers to make sure they agree, or

compensate accordingly.

Follow this procedure:

1. Open supply air registers and return air grilles.

Make sure the registers and grilles are free of

obstruction from rugs, carpets, drapes or furniture.

7. Set room thermostat on highest temperature

setting. Operate furnace 10 minutes. Record

supply air and return air temperatures.

8. Calculate air temperature rise by subtracting return

air temperature from supply air temperature.

•

If air temperature rise is above the temperature

rise range on rating plate, furnace is overfired

or has insufficient airflow. Check gas input

following the instructions in Section ,

"Checking Gas Input Rate". If air temperature

rise is still above temperature rise range

specified, more heating air flow is needed.

Check duct work and grilles to make sure all

are properly sized.

•

If air temperature rise is below the temperature

rise range on rating plate, furnace is underfired

or has too much airflow. Check gas input

following the instructions in Section ,

"Checking Gas Input Rate". If air temperature

rise is still below temperature rise range

specified, less heating air flow is needed.

Adjust dampers or grilles as needed.

•

After making adjustments, you must check air

temperature rise to verify that resulting air

temperature rise is within allowable range. If

air temperature rise is still outside the

temperature rise range specified on rating

plate, check duct system design with a

qualified heating engineer. It may be

necessary to re-size the duct work. Recheck

air temperature rise after revising duct systems.

9. Set room thermostat to desired setting.

10. Remove thermometers and seal duct work holes.

NOTE: Failure to seal holes could result in reduced

system performance.

22. CONVERSION OF GAS INPUT BTUH

FROM HIGH TO LOW RATING

All the derated WG series units are produced with

maximum BTUH input orifices installed. To field

convert input, a change to main burner orifices is

required.

NOTE:

No change to air orifices is necessary. A set

of low input orifices is shipped with every

unit. They will be found packaged in a bag

behind the burner door. Refer to the unit

rating plate to confirm the proper orifice

size. Proper installation of the orifices is

detailed as follows:

A. Shut off electrical supply to the unit.

B. Shut off gas supply to the unit.

C. Remove burner access panel.

D. Disconnect gas valve from gas supply piping.

E. Disconnect the two wires from the gas valve.

F.

Remove the manifold assembly so that orifices

are now accessible and remove orifices.

G. Apply a modest amount of pipe compound to the

new orifices and screw them into the manifold.

H. To assemble burner reverse steps A through G.

2. Set balancing dampers in supply duct system.

3. Check duct work for obstructions or leaks.

4. Make sure filters are clean and in place.

5. Place one thermometer in supply air plenum

approximately 2 feet from furnace. Locate

thermometer tip in center of plenum to ensure

proper temperature measurement.

6. Place second thermometer in return air duct

approximately 2 feet from furnace. Locate

thermometer tip in center of duct to ensure proper

temperature measurement.

WARNING

Failure to follow these instructions could create

a hazard resulting in property damage, bodily

injury, or death.

Summary of Contents for WG421

Page 8: ...Manual 2100 365 Page 5 MIS 1352 FIGURE 1 UNIT DIMENSIONS...

Page 12: ...Manual 2100 365 Page 9 FIGURE 4 MOUNTING INSTRUCTIONS MIS 1472...

Page 15: ...Manual 2100 365 Page 12 FIGURE 8 COMMON WALL MOUNTING INSTALLATIONS MIS 1474...

Page 20: ...Manual 2100 365 Page 17 FIGURE 11 LOW VOLTAGE WIRING MIS 1162...

Page 21: ...Manual 2100 365 Page 18 FIGURE 12 GAS PIPE CONNECTION MIS 1478...

Page 29: ...Manual 2100 365 Page 26 26 LIGHTING AND SHUTDOWN INSTRUCTIONS FIGURE 14 INSTRUCTION LABEL...

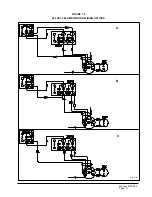

Page 34: ...Manual 2100 365 Page 31 FIGURE 18 460 VOLT BLOWER MOTOR WIRING OPTIONS MIS 1487 A B C...

Page 41: ...Manual 2100 365 Page 38...

Page 42: ...Manual 2100 365 Page 39...

Page 43: ...Manual 2100 365 Page 40...

Page 44: ...Manual 2100 365 Page 41...

Page 45: ...Manual 2100 365 Page 42...

Page 46: ...Manual 2100 365 Page 43...

Page 47: ...Manual 2100 365 Page 44...

Page 48: ...Manual 2100 365 Page 45...

Page 49: ...Manual 2100 365 Page 46...

Page 50: ...Manual 2100 365 Page 47...

Page 51: ...Manual 2100 365 Page 48...

Page 52: ...Manual 2100 365 Page 49...