Manual 2100-486D

Page

6 of 37

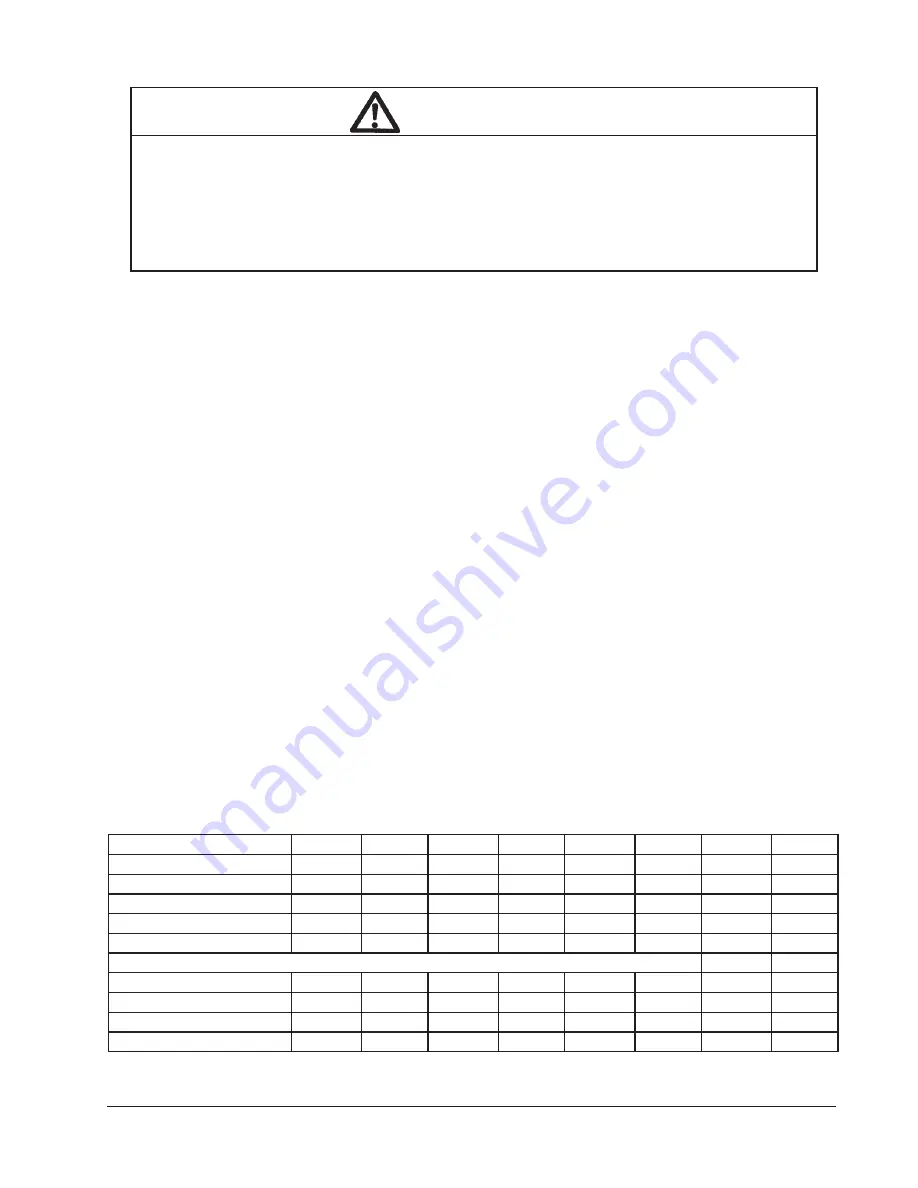

TABLE 1

SPECIFICATIONS

WF050, WF075, WF100, WF125 MODELS

*

75 degree C Copper wire size

l

e

d

o

M

A

-

0

5

0

F

W

K

-

0

5

0

F

W

A

-

5

7

0

F

W

K

-

5

7

0

F

W

A

-

0

0

1

F

W

K

-

0

0

1

F

W

A

-

5

2

1

F

W

K

-

5

2

1

F

W

Z

H

0

6

–

g

n

i

t

a

R

l

a

c

i

r

t

c

e

l

E

1

-

0

6

-

8

0

2

/

0

3

2

1

-

0

6

-

5

1

1

1

-

0

6

-

8

0

2

/

0

3

2

1

-

0

6

-

5

1

1

1

-

0

6

-

8

0

2

/

0

3

2

1

-

0

6

-

5

1

1

1

-

0

6

-

8

0

2

/

0

3

2

1

-

0

6

-

5

1

1

y

t

i

c

a

p

m

A

t

i

u

c

r

i

C

m

u

m

i

n

i

M

1

.

7

1

.

7

1

.

7

1

.

7

1

.

7

1

.

7

1

.

7

1

.

7

*

e

z

i

S

e

r

i

W

d

l

e

i

F

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

e

z

i

S

e

r

i

W

d

n

u

o

r

G

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

.

x

a

M

–

e

s

u

F

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

r

o

t

a

r

o

p

a

v

E

d

n

a

r

o

t

o

M

D

P

S

/

M

P

R

/

P

H

–

r

o

t

o

M

r

e

w

o

l

B

3

/

5

7

0

1

/

3

/

1

3

/

5

7

0

1

/

3

/

1

3

/

5

7

0

1

/

3

/

1

3

/

5

7

0

1

/

3

/

1

3

/

5

7

0

1

/

3

/

1

3

/

5

7

0

1

/

3

/

1

3

/

5

7

0

1

/

3

/

1

3

/

5

7

0

1

/

3

/

1

s

p

m

A

–

r

o

t

o

M

r

e

w

o

l

B

2

.

2

6

.

4

2

.

2

6

.

4

2

.

2

6

.

4

2

.

2

6

.

4

.

P

.

S

.

E

M

F

C

2

.

–

0

0

0

1

2

.

–

0

0

0

1

2

.

–

0

0

0

1

2

.

–

0

0

0

1

2

.

–

0

0

0

1

2

.

–

0

0

0

1

2

.

–

0

0

0

1

2

.

–

0

0

0

1

)

s

e

h

c

n

I

(

s

e

z

i

S

r

e

t

l

i

F

2

x

5

2

x

0

2

2

x

5

2

x

0

2

2

x

5

2

x

0

2

2

x

5

2

x

0

2

2

x

5

2

x

0

2

2

x

5

2

x

0

2

2

x

5

2

x

0

2

2

x

5

2

x

0

2

1.

IMPORTANT

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians. All duct work or portions thereof not in

the conditioned space should be properly insulated in

order to both conserve energy and prevent condensation

or moisture damage.

2. APPLICATION

This is a fan-assisted forced air gas furnace for outdoor

installation. A fan-assisted furnace is equipped with an

integral mechanical means to draw products of

combustion through the combustion chamber and heat

exchanger. The furnace installation must conform with

local building codes and ordinances or, in their

absence, with the National Fuel Gas Code ANSI

Z223.1 or CAN/CGA-B149.1, latest edition, and the

National Electrical Code ANSI/NFPA-7 or CSA C22.1,

latest edition. It is the personal responsibility and

obligation of the purchaser to contact a qualified

installer to assure that installation is adequate and is in

conformance with governing codes and ordinances.

3.

DUCT WORK

The unit is designed for use with or without duct work.

See Warning on Page 8. Flanges are provided for

attaching the supply and return ducts. These

instructions explain the recommended method to

installing the gas heating unit and the electrical wiring

connections and gas piping to the unit. All internal

wiring is complete.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

heating system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

All duct work, supply and return, must be properly sized

for the design airflow requirement of the equipment.

Air Conditioning Contractors of America (ACCA) is an

excellent guide to proper sizing.

CAUTION

During the initial firing of the burners there will probably be some amount of smoke issued to the

circulating air stream as the result of residual oil burning off of the heat exchanger tubes. This oil

is required during the forming process of the stainless steel heat exchanger tubes to facilitate the

bending. OSHA or the National Toxicology Program does not list the oil as a carcinogen. In

vapor form this may be irritating to the eyes or could cause headaches. This is a one-time

occurrence, and ventilation of the space may be required depending upon the space being

conditioned.

Summary of Contents for WF0501-A

Page 13: ...Manual 2100 486D Page 13 of 37 FIGURE 6 COMMON WALL MOUNTING INSTALLATIONS...

Page 19: ...Manual 2100 486D Page 19 of 37 FIGURE 11 LOW VOLTAGE WIRING...

Page 20: ...Manual 2100 486D Page 20 of 37 FIGURE 12 GAS PIPE CONNECTION...

Page 34: ...Manual 2100 486D Page 34 of 37 230 208 60 1...

Page 35: ...Manual 2100 486D Page 35 of 37 115 60 1...