- 58 -

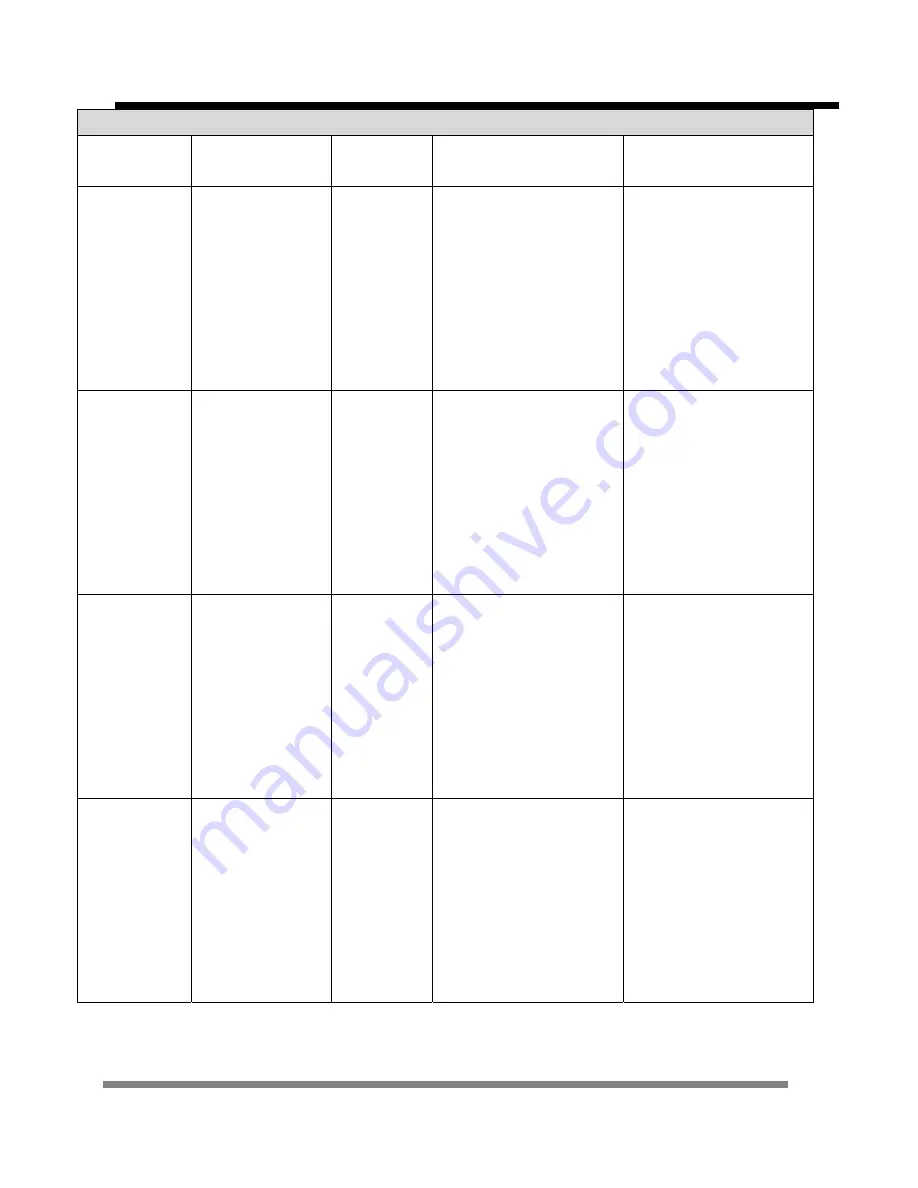

Barco RLM W6 Operation Commands

Command

Item

Operation Commands

Values

Notes

6-12

btn.2 =

?

0 = HDMI 1

1 = HDMI 2

2 = RGB D-15

3 = YUV 1

4 = RGBHV/YUV2

5 = Composite Video

6 = S-Video

7 = RGB-S

6-13

btn.3 =

?

0 = HDMI 1

1 = HDMI 2

2 = RGB D-15

3 = YUV 1

4 = RGBHV/YUV2

5 = Composite Video

6 = S-Video

7 = RGB-S

6-14

btn.4 =

?

0 = HDMI 1

1 = HDMI 2

2 = RGB D-15

3 = YUV 1

4 = RGBHV/YUV2

5 = Composite Video

6 = S-Video

7 = RGB-S

6-15

btn.5 =

?

0 = HDMI 1

1 = HDMI 2

2 = RGB D-15

3 = YUV 1

4 = RGBHV/YUV2

5 = Composite Video

6 = S-Video

7 = RGB-S

Summary of Contents for RLM W6

Page 1: ... 1 SERVICE MANUAL BARCO RLM W6 ...

Page 17: ... 17 Troubleshooting Error Code System Flow chart Lamp Ignition System status ...

Page 18: ... 18 ...

Page 19: ... 19 ...

Page 20: ... 20 ...

Page 25: ... 25 J7 Inlet Ti sensor J11 DMD Tc sensor J21 Lamp A LAMP BALLAST BD J24 Lamp B ...

Page 36: ... 36 ...

Page 37: ... 37 Figure 2 IR Reception Angles Remote Control Installation ...

Page 38: ... 38 z Software Download Process Projector firmware Download procedures ...

Page 47: ... 47 3 11 RJ 45 Test procedures Key in your Projector IP to web browser Information ...

Page 65: ... 65 z Block Diagram All Function ...

Page 66: ... 66 Power Function Dual Ballast 280W x 2 CN102 Q106 ...

Page 68: ... 68 z Board Location ...

Page 95: ... 95 27 Loosen 7 pcs M4 10 screws on the bottom of DMD engine ...

Page 96: ... 96 28 Tear down the DMD engine 29 Loosen 1 pc M3 6 screw on the front of Lamp module base ...

Page 103: ... 103 ...

Page 104: ... 104 Wire Clip Dressing A ...

Page 105: ... 105 B ...

Page 110: ... 110 Please refer to Page 126 Page 131 3 4 5 6 7 8 ...

Page 111: ... 111 9 10 11 12 ...

Page 112: ... 112 13 14 15 16 17 18 FAN KIT 1 FAN 7 ...

Page 116: ... 116 z Unpack the unit ...

Page 117: ... 117 Carton Out Dim 669 157 175 Empty carton inside nothing Carton inside Lamp ...

Page 119: ... 119 ...

Page 126: ... 126 Finish photo ...

Page 129: ... 129 Item 3 Screw M2 0 4 x 4 Item 2 Wire saddle x 1 Item 1 Motor cover x 1 ...

Page 130: ... 130 Item 2 Screw M4 0 7 x 3 Item 1 Clip Lens Assy x 3 ...

Page 131: ... 131 Item 3 Screw M4 0 7 x 2 Item 2 Clip fixed cover x 2 Item 1 Lens cover x 1 ...

Page 132: ... 132 Item 1 Cable Tie x 3 ...