Summary of Contents for DP-1500

Page 1: ...DP 1500 Installation manual R59770091 06 06 01 2009 ...

Page 14: ...1 Operating conditions 10 R59770091 DP 1500 06 01 2009 ...

Page 32: ...3 Mechanical set up of the DP 1500 28 R59770091 DP 1500 06 01 2009 ...

Page 48: ...5 Lenses lens holder 44 R59770091 DP 1500 06 01 2009 ...

Page 66: ...6 Lamp lamp house 62 R59770091 DP 1500 06 01 2009 ...

Page 84: ...9 Starting up 80 R59770091 DP 1500 06 01 2009 ...

Page 92: ...10 Projector registration Image 10 9 Add new owner 88 R59770091 DP 1500 06 01 2009 ...

Page 126: ...12 Servicing 122 R59770091 DP 1500 06 01 2009 ...

Page 142: ...13 Removal and installation of projector covers 138 R59770091 DP 1500 06 01 2009 ...

Page 143: ...A Specifications A SPECIFICATIONS R59770091 DP 1500 06 01 2009 139 ...

Page 144: ...A Specifications 140 R59770091 DP 1500 06 01 2009 ...

Page 146: ...A Specifications 142 R59770091 DP 1500 06 01 2009 ...

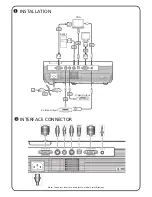

Page 154: ...C Pin configurations 150 R59770091 DP 1500 06 01 2009 ...

Page 155: ...D Order info D ORDER INFO R59770091 DP 1500 06 01 2009 151 ...

Page 156: ...D Order info 152 R59770091 DP 1500 06 01 2009 ...

Page 158: ...D Order info 154 R59770091 DP 1500 06 01 2009 ...