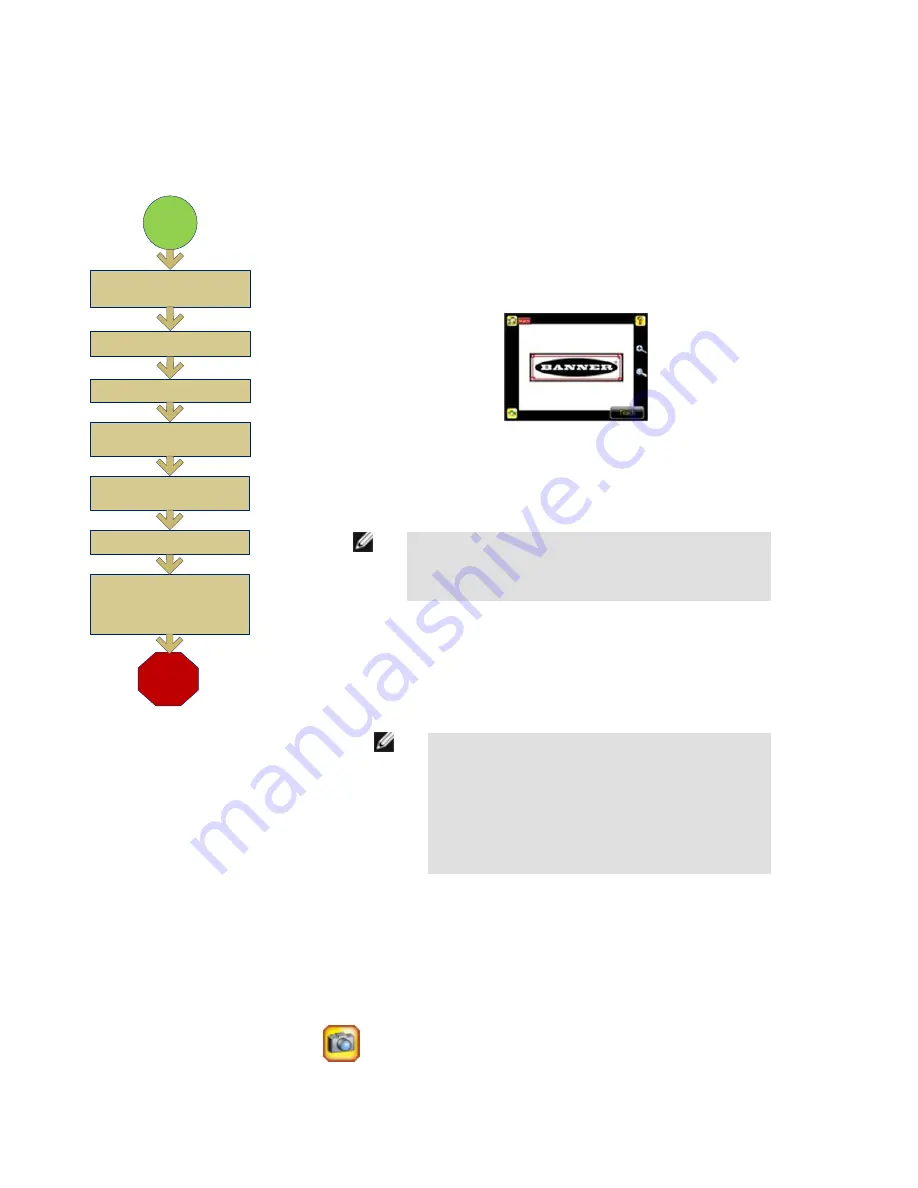

Configuring a Match Sensor

Finish

Adjust Percent Match

(Optional)

Start

Adjust Rotation Range

(Optional)

Set Pass Count

Use Manual Trigger to Test

Range of Good and Bad

Parts

Select ROI Type and

Adjust

Click Teach

Click Outside ROI

NOTE: Under normal operation

any parameter modifications take

effect on the next trigger.

The flow chart at left provides an overview of the steps to setting up an inspection on the iVu TG

sensor as a Match sensor.

1. Make sure you use a good part for the inspection setup. Normally, the part will be centered

in the field of view with the feature of interest surrounded by the Region of Interest (ROI), a

blue rectangle. The ROI can be rotated and resized. The ROI turns red when selected for

adjustment.

2. Select the ROI by clicking inside it. Move it, resize it, and rotate it by dragging the ROI or its

corners. Once the feature of interest is within the ROI, click the Teach button. The feature

will be highlighted in green.

NOTE: When running a Match inspection, the sensor will look

for any possible patterns to match anywhere within the field of

view.

3. Configure the following parameters:

• The Percent Match setting adjusts how closely the inspected part or label needs to

match the reference part or label. The Percent Match scale is from 0 to 100, where 0 is

the most tolerant and 100 is the least tolerant. Move the slider to the left or to the right to

adjust the setting. For the best results, use a value from 50 to 90.

NOTE: When running a Match inspection, the sensor will

highlight in green any pattern matches that are within the

specified Rotation Range and meet or exceed the value

specified for Percent Match. Patterns that are within the

specified Rotation Range and within approximately 20% be-

low the specified value for Percent Match will be colored

yellow.

• The Rotation Range sets the expected rotation of parts or labels during an inspection.

For example, a value of 45 means that the part may rotate 45 degrees in either direction

from the reference part and still pass. Move the slider from 0 to 180 degrees. Note that

the smaller the rotation range, the faster the inspection will run.

• The Minimum Pass Count is the minimum number of parts, labels, or features expected

to fall within the specified criteria; the Maximum Pass Count is the maximum number

expected to fall within the specified criteria. These settings are used to determine the

pass or fail result of the inspection.

4.

Use the Manual Trigger, located in the lower-right corner of the screen, to test good

and bad parts. Adjust settings as necessary and retest.

Rev. C

www.bannerengineering.com - tel: 763-544-3164

13