Configuring an Area Sensor

Finish

Set Pass Count

Start

Use Manual Trigger to Test

Range of Good and Bad

Parts

Select ROI Type and

Adjust

Adjust Intensity Range

Adjust Area Range

NOTE: Make sure you test a

range of samples checking that

the "worst" good part passes, and

the "best" bad part fails.

The flow chart at left provides an overview of the steps to setting up an inspection on the iVu TG

sensor as an Area sensor.

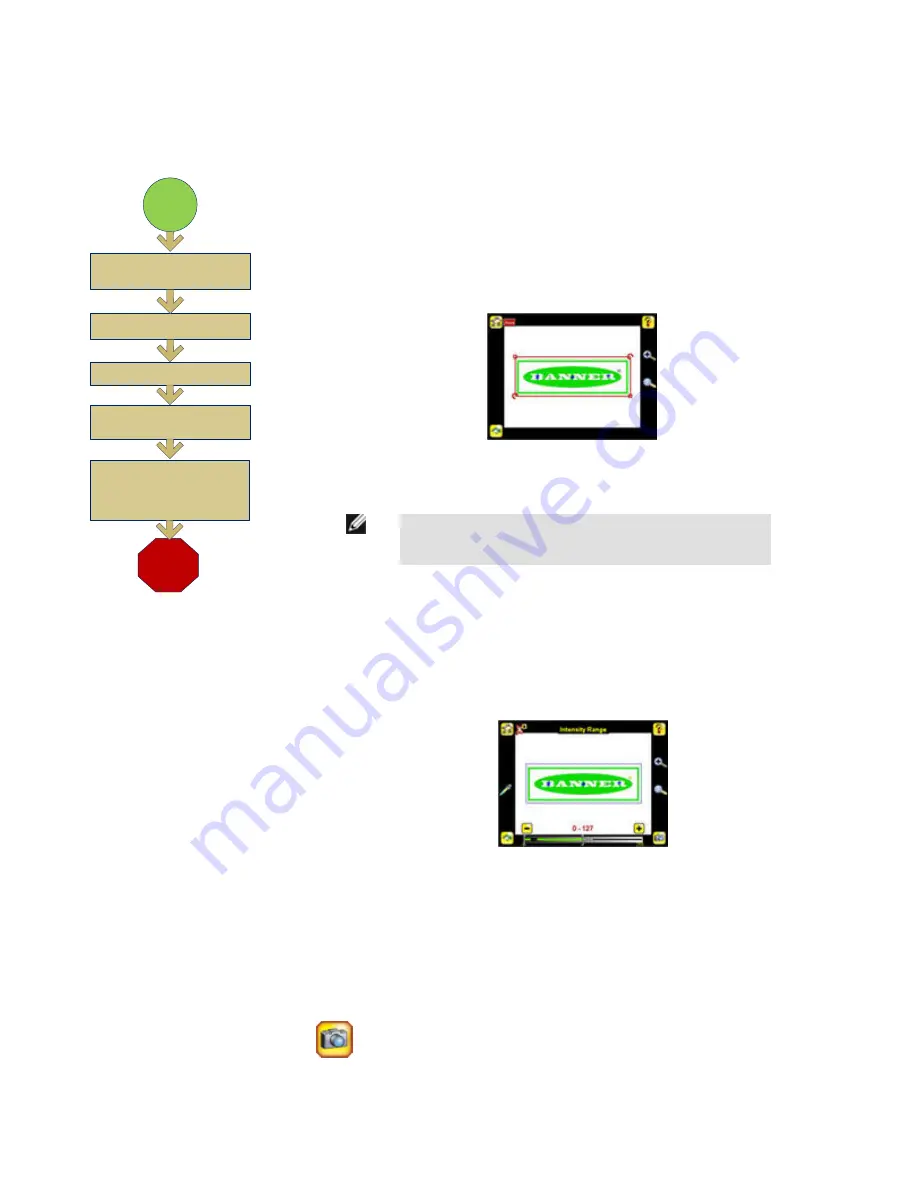

1. Make sure you have a good part to use for the inspection setup. Normally, the part being in-

spected is centered in the field of view with the feature of interest surrounded by the Region of

Interest (ROI), the blue rectangle. The ROI can be rotated and resized, and is red when selec-

ted for adjustment.

2. Adjust the ROI so that the part is within the ROI. The pattern will be highlighted in green.

NOTE: When running an Area inspection, the sensor will only

find objects within the ROI.

3. Set the following parameters:

• Intensity Range is the range of gray scale values the sensor should look for. To set the

Intensity Range, use the eye dropper on the left of the screen to select the target feature,

then use the slider bar at the bottom of the display to fine-tune the selection. As the slider

bar is moved, green highlighted areas indicate objects the sensor finds and counts. The

objects colored yellow are found, but filtered out (that is, not counted) because the objects

fall outside of the Area Range.

• The Area Range is used to set the size limits of a feature of interest. Use the slider bar at

the bottom of the display to select the range. Areas are measured by counting pixels. For

example, a rectangular feature that is 100 pixels wide by 200 pixels tall will have an area

of roughly 20,000 pixels.

4. The Minimum Pass Count is the minimum number of parts, labels, or features expected to

fall within the specified criteria; the Maximum Pass Count is the maximum number expected

to fall within the specified criteria. These settings are used to determine the pass or fail result

of the inspection.

5.

Use the Manual Trigger, located in the lower-right corner of the screen, to test good

and bad parts. Adjust settings as necessary and retest.

Rev. C

www.bannerengineering.com - tel: 763-544-3164

11