Bandit

61

Copyright 9/18

MODEL 15XP/1390

Before attempting any type of maintenance, disengage clutch, wait for the disc/drum to come to a complete

stop, turn off engine, remove the ignition key, make sure the ignition key is in your possession, install the

disc/drum lock pin, and disconnect the battery.

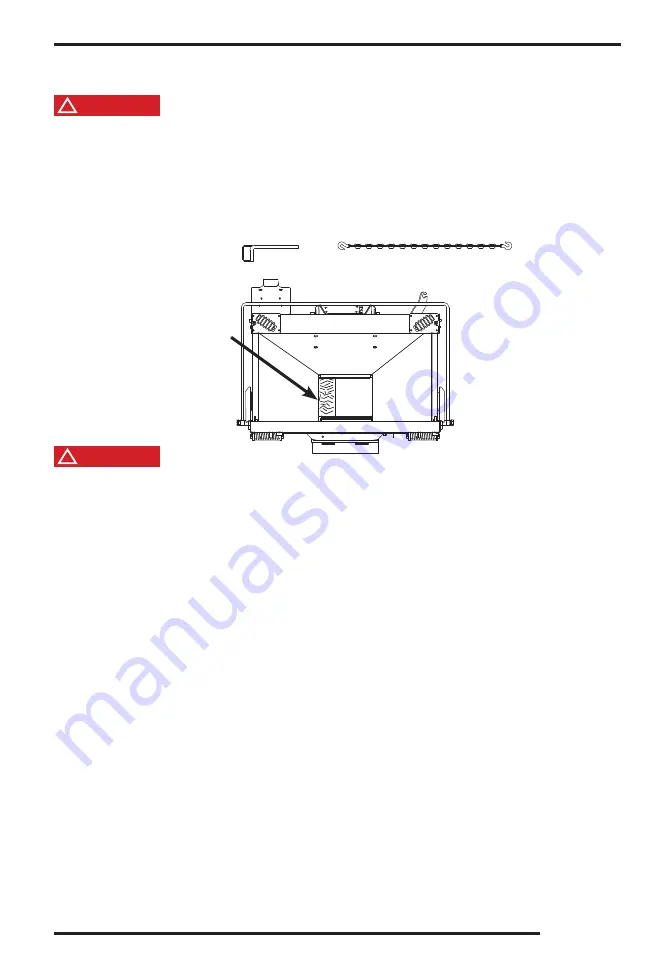

Before working inside the infeed hopper or under the top feedwheel remove the yoke springs from the

top yoke, raise the yoke , install the yoke lock pin, safety chain the yoke in the raised position, and insert a

wooden block to assist in holding the yoke in the raised position.

DANGER

!

CHECK THE ANVIL TO KNIFE CLEARANCE

1. This clearance should be checked on a weekly basis or as knives are changed. To check the anvil

clearance, follow all pre-maintenance shut down procedures. Once all safety procedures are

completed the anvil to knife clearance can be checked.

2. In order to check the clearance one person will need to climb into the infeed hopper. Use a feeler

gauge or the anvil to knife gauge supplied by Bandit to check the clearance of the first knife to the

anvil. Check the clearance at the left and right sides of the knife.

3. Once that knife has been checked climb back out of the infeed hopper, remove the drum lock pin,

and very carefully rotate the chipper drum so the other knives can be checked.

4. Once all knives have been checked adjust the anvil according to the closest knife. The anvil to knife

clearance should be .120 inches (3.0 mm).

5. Set the closet knife to this distance.

Do Not under any circumstance attempt to rotate the chipper drum while someone is inside the infeed

hopper. They may become seriously injured, Do Not Do This!

ANVIL ADJUSTMENT PROCEDURE

1. To adjust the anvil first loosen two of the hex nuts on either the inside or outside of the anvil puller

block. If the anvil needs to be adjusted closer to the drum, loosen the outside anvil adjuster hex

nuts. If the anvil needs to be adjusted away from the drum, loosen the inside anvil adjuster hex nuts.

2. Loosen the anvil bolts from underneath the machine.

3. Once the components have been loosened, move the anvil to the correct clearance using the anvil

adjuster bolts and hex nuts.

4. Once the knife is set to the correct clearance, .120 inches (3.0 mm), retighten all components..

5. Make sure bolts are torqued to their specific bolt torques refer to bolt torques on page 44.

6. Carefully rotate the chipper drum to make sure all the knives clear the anvil.

MAINTENANCE

ANVIL ADJUSTMENT

DANGER

!

Use Chain

Use Wooden

Block

Use Yoke

Lock Pin