IT5000-C / IT6000-C

3/8” IT Tool

www.BAND-IT-IDEX.com

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 25 of 36

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Operating

Manual

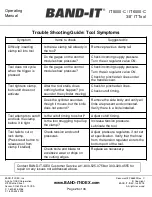

If the tool fails to fully tension the clamp:

Failure to fully tension the clamp can be caused by a variety of factors. The two

most common factors are incorrect tension pressure and problems with the grippers.

•

Check tension pressure setting on Tension Pressure Gauge of Air Controller Module.

Adjust pressure per the settings found in the “Air System Settings” page.

•

Evaluate the clamp tail dimple pattern. If elongated dimples are present, the problem

may be with the Tension Block or Front Gripper.

•

If a problem is indicated, follow the instructions in the “Maintenance” section to remove

and inspect the tension block assembly and the front gripper.

•

Examine the Tension Block and Tension Gripper for damage or wear.

•

Examine the Front Gripper area for foreign debris and/ or buildup of metal shavings.

•

Ensure that the four cutter blade screws are tightened.

•

If excessive damage or wear is determined, replace the worn parts.

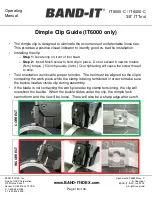

Normal clamp tail dimple

pattern.

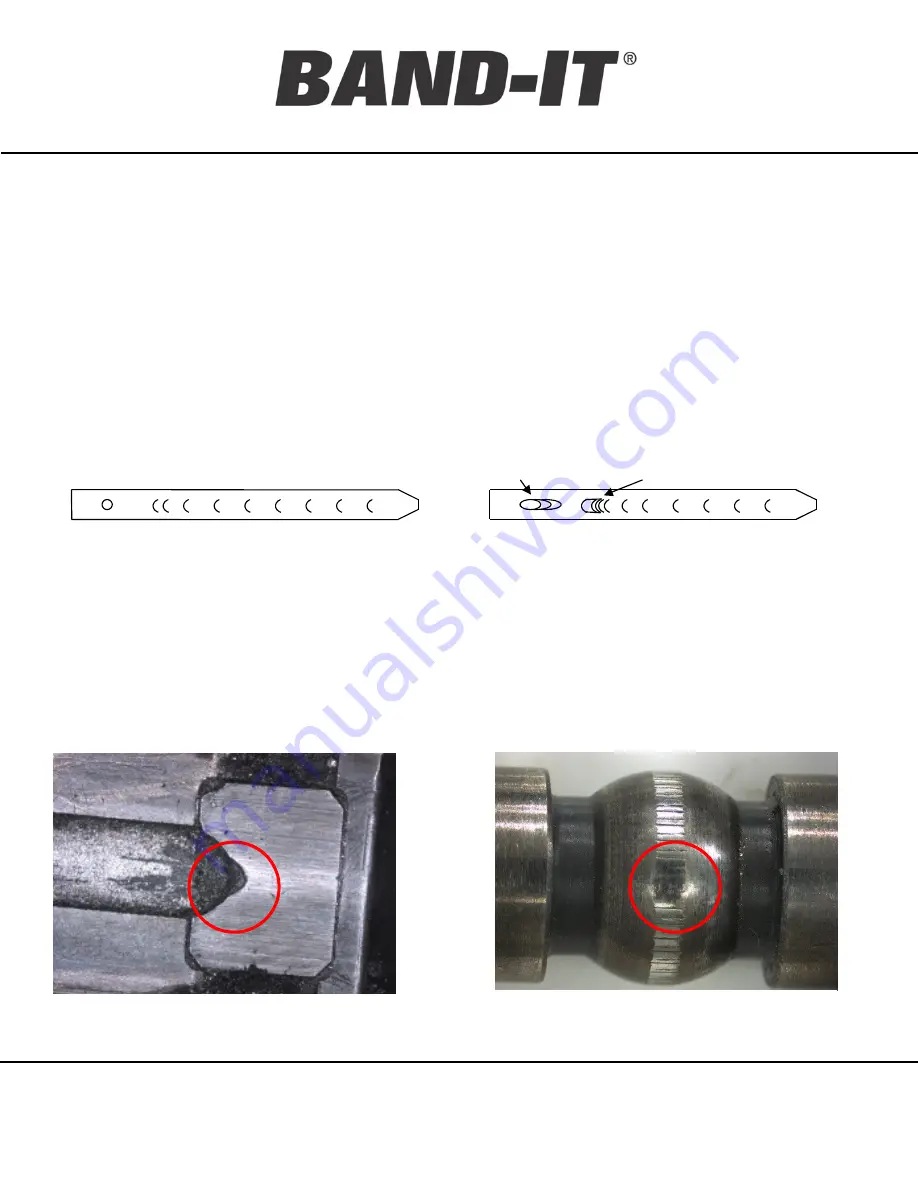

Front Gripper Tension Block

A worn out tension block:

Edge is no longer sharp, or is chipped

Clamp tail dimple pattern

indicates a problem

Trouble Shooting Guide: Unable to Achieve Tension

A worn out tension gripper:

Ridges are worn off in some sections