ENGLISH

29 / 60

0006160032_201711

OPERATION DESCRIPTION WITH GASEOUS

FUEL

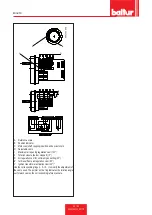

Burner operation is fully automatic; it starts up by enabling the main

switch and the control panel switch.

Burner operation is managed by the electronic command and control

equipment.

Blown air burners with electronic modulation may be used on hearths

under strong pressure or in a vacuum, according to the corresponding

operating curves.

They combine a very stable flame with total safety and high

performance.

The burner is fitted with an electronic cam controlled by a

microprocessor for intermittent operation, and for the control and

monitoring of the blown air gas burners. Electronic modulation

achieved by means of two step air gas regulation motors.

The burner is fitted with a valve tightness control device. To better

understand the operation of the electronic cam, read the specific

instructions in the manual provided carefully.

The term two-stage progressive operation indicates that transition

from the first to the second state (from minimum to maximum

operation) is progressive in terms of both amount of combustion air

let in and the amount of output fuel. This results in a greater pressure

stability in the gas supply network.

Ignition is preceded by the combustion chamber pre-ventilation as set

forth by the Standards, with air open and with a duration of approx.

30 seconds.

If the air pressure switch has detected a sufficient pressure, the

ignition transformer activates at the end of the ventilation phase and

after 3 seconds the safety and main valves open in sequence.

Gas reaches the combustion head, mixes with air supplied by the fan

and is ignited. The gas supply is regulated by the butterfly gas valve.

Three seconds after the valves (main and safety) come on, the ignition

transformer goes off. Thus the burner is ignited at the ignition point.

Flame presence is detected by the dedicated control device (UV

photocell).

The programmer relay moves past the locking position and sends

voltage to the (air / gas) supply regulation servo motors, which go to

the minimum point (200).

If the second stage boiler thermostat (or pressure switch) allows

it (set to a temperature or pressure value higher than the existing

value in the boiler), the (air / gas) supply servo motors will start to

turn, gradually increasing gas and combustion air supplies up to the

maximum supply to which the burner has been set (999).

The burner remains in the maximum output position as long as the

temperature or pressure reaches a value sufficient enough to cause

the intervention of the probe that rotates the gas/air flow rate regulation

servomotors. This progressively reduces the gas, combustion air and

motor's RPM (if the inverter is fitted) to the minimum.

If the threshold value (temperature or pressure), to which the complete

shut-down device (thermostat or pressure switch) is set, is reached

even with minimum gas and air output, the burner will be shut down

when the device is triggered.

As the temperature or pressure drops below the shut-down device's

(thermostat or pressure switch) set point, the burner will be turned on

again as described above.

During normal operation, the modulation probe installed on the

boiler measures any variation demands and automatically adjusts

the fuel and combustion air flow rate by starting the air/gas flow rate

modulation servomotors, modulating the output.

This causes the air/gas output control system to balance the amount

of heat supplied to the boiler with the amount it gives off during use.

Summary of Contents for TBML 80 ME

Page 2: ......

Page 4: ...ITALIANO 2 60 0006160032_201711 ITALIANO Schemi elettrici 48...

Page 50: ...ITALIANO 48 60 0006160032_201711 SCHEMI ELETTRICI...

Page 51: ...ITALIANO 49 60 0006160032_201711...

Page 52: ...ITALIANO 50 60 0006160032_201711...

Page 53: ...ITALIANO 51 60 0006160032_201711...

Page 54: ...ITALIANO 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 56: ...ITALIANO 54 60 0006160032_201711...

Page 57: ...ITALIANO 55 60 0006160032_201711...

Page 58: ...ITALIANO 56 60 0006160032_201711...

Page 59: ...ITALIANO 57 60 0006160032_201711...

Page 60: ...ITALIANO 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 62: ......

Page 64: ...ENGLISH 2 60 0006160032_201711 ENGLISH Wiring diagrams 48...

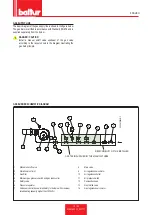

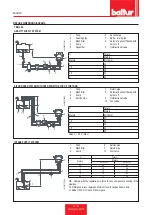

Page 110: ...ENGLISH 48 60 0006160032_201711 WIRING DIAGRAMS...

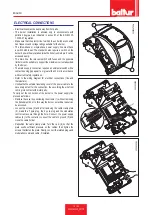

Page 111: ...ENGLISH 49 60 0006160032_201711...

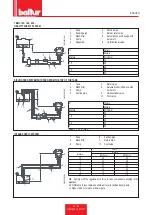

Page 112: ...ENGLISH 50 60 0006160032_201711...

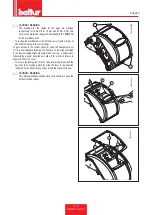

Page 113: ...ENGLISH 51 60 0006160032_201711...

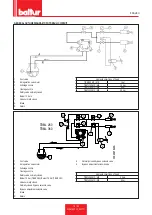

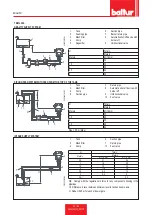

Page 114: ...ENGLISH 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 116: ...ENGLISH 54 60 0006160032_201711...

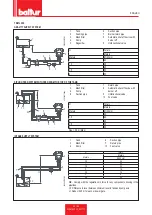

Page 117: ...ENGLISH 55 60 0006160032_201711...

Page 118: ...ENGLISH 56 60 0006160032_201711...

Page 119: ...ENGLISH 57 60 0006160032_201711...

Page 120: ...ENGLISH 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 122: ......

Page 123: ......