ENGLISH

43 / 60

0006160032_201711

EXPECTED LIFESPAN

The expected lifespan of burners and relevant components depends very much from the type of application on which the burner is installed, from

cycles of delivered power, from the conditions of the environment in which it is located, from maintenance frequency and mode, etc.

Standards about safety components provide for a project expected lifespan expressed in cycles and/or years of operation.

Such components ensure the correct operation in standard (*) operating conditions, with periodic maintenance according to the instructions

contained in the manual.

The table below shows the project expected lifespan of the main safety components; approximately, operating cycles correspond to the burner

activations.

When this expected lifespan limit has almost been reached the component must be replaced with an original spare part

.

IMPORTANT

warranty conditions (laid down in contracts and/or delivery or payment notes, if necessary) are independent and do not refer to the

expected lifespan stated below.

(*) “Normal” operating conditions means applications on water boilers and steam generators or industrial applications compliant with the standard

EN 746, in environments with temperatures within the limits provided for in this manual and with pollution degree 2 in compliance with annex M

of the standard EN 60335-1.

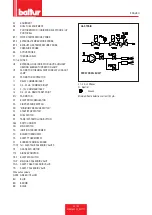

Safety component

Project expected lifespan

Operating cycles

Years of operation

Control box

250 000

10

Flame sensor (1)

N.A.

10,000 operating hours

Seal control

250 000

10

Gas pressure switch

50 000

10

Air pressure switch

250 000

10

Gas pressure regulator (1)

N.A.

15

Gas valves (with seal check)

Until the first seal fault signal

Gas valves (without seal check) ( 2)

250 000

10

Servomotors

250 000

10

Liquid fuel hoses

N.A.

5 (every year for fuel oil burners or in the presence

of biodiesel in diesel/kerosene)

Liquid fuel valves

250 000

10

Air fan impeller

50,000 activations

10

(1) The characteristics can degrade over time; during the annual maintenance the sensor must be checked and in case of flame signal degradation

must be replaced.

(2) Using normal mains gas.

Summary of Contents for TBML 80 ME

Page 2: ......

Page 4: ...ITALIANO 2 60 0006160032_201711 ITALIANO Schemi elettrici 48...

Page 50: ...ITALIANO 48 60 0006160032_201711 SCHEMI ELETTRICI...

Page 51: ...ITALIANO 49 60 0006160032_201711...

Page 52: ...ITALIANO 50 60 0006160032_201711...

Page 53: ...ITALIANO 51 60 0006160032_201711...

Page 54: ...ITALIANO 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 56: ...ITALIANO 54 60 0006160032_201711...

Page 57: ...ITALIANO 55 60 0006160032_201711...

Page 58: ...ITALIANO 56 60 0006160032_201711...

Page 59: ...ITALIANO 57 60 0006160032_201711...

Page 60: ...ITALIANO 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 62: ......

Page 64: ...ENGLISH 2 60 0006160032_201711 ENGLISH Wiring diagrams 48...

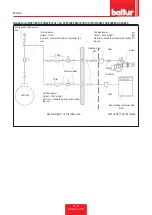

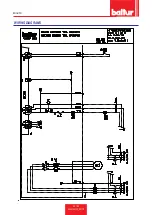

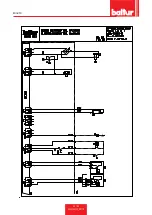

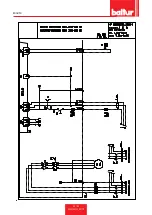

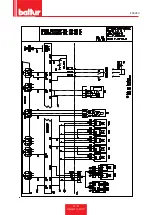

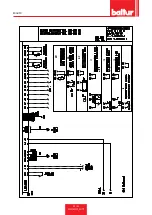

Page 110: ...ENGLISH 48 60 0006160032_201711 WIRING DIAGRAMS...

Page 111: ...ENGLISH 49 60 0006160032_201711...

Page 112: ...ENGLISH 50 60 0006160032_201711...

Page 113: ...ENGLISH 51 60 0006160032_201711...

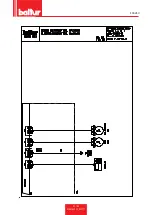

Page 114: ...ENGLISH 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

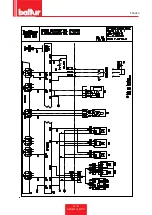

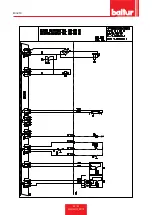

Page 116: ...ENGLISH 54 60 0006160032_201711...

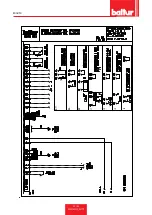

Page 117: ...ENGLISH 55 60 0006160032_201711...

Page 118: ...ENGLISH 56 60 0006160032_201711...

Page 119: ...ENGLISH 57 60 0006160032_201711...

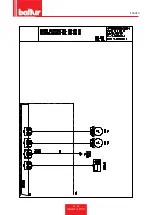

Page 120: ...ENGLISH 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 122: ......

Page 123: ......