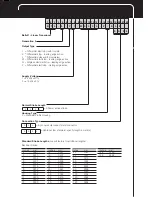

BTL5-P/I/K/L/M_-M/U_ _ _ _-P-S32/KA_ _

Micropulse Linear Transducer

Digital Output / Profile Housing

Read this manual before installing and operating the Micropulse

Transducer.

1.1 Proper application

The BTL5 Micropulse transducer is intended to be installed in a

machine or system. Together with a controller (PLC) or a proces-

sor (BTA) it comprises a position measuring system and may only

be used for this purpose.

Unauthorized modifications and non-permitted usage will result in

the loss of warranty and liability claims.

1.2 Qualified personnel

This guide is intended for specialized personnel who will perform

the installation and setup of the system.

1.3 Use and inspection

The relevant safety regulations must be followed when using the

transducer system. In particular, steps must be taken to ensure

that should the transducer system become defective no hazards to

persons or property can result. This includes the installation of

additional safety limit switches, emergency shutoff switches and

maintaining the permissible ambient conditions.

1.4 Scope

This guide applies to the model

BTL5-P/I/K/L/M...P... Micropulse

transducer.

An overview of the various models

can be found in section 6 Versions

(indicated on product label)

on page 7.

1 Safety Advisory

Contents

1

Safety Advisory ............... 2

1.1

Proper application .............. 2

1.2

Qualified personnel ............ 2

1.3

Use and inspection ............ 2

1.4

Scope ................................ 2

2

Function and

Characteristics ............... 3

2.1

Characteristics .................. 3

2.2

Function ............................. 3

2.3

Available stroke lengths

and magnets ..................... 3

3

Installation ..................... 3

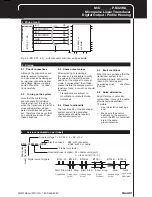

3.1

Transducer installation ...... 3

3.2

Floating magnets ............... 4

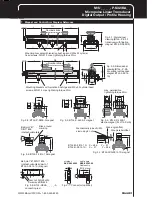

3.3

Captive magnets ............... 5

4

Wiring .............................. 6

5

Startup ............................. 7

5.1

Check connections ........... 7

5.2

Turning on the system ....... 7

5.3

Check output values ......... 7

5.4

Check functionality ............ 7

5.5

Fault conditions ................. 7

5.6

Noise elimination ............... 7

6

Versions

(indicated on part label) 7

7

Technical Data ............... 8

7.1

Dimensions, weights,

ambient conditions ............ 8

7.2

Supply voltage (external) .... 8

7.3

Control signals .................. 8

7.4

Connection to processor ... 8

7.5

Included in shipment ......... 8

7.6

Magnets (order separately) 8

7.7

Accessories (optional) ....... 8

7.8

Compatible processors

and displays ...................... 8

Note:

For special versions,

which are indicated by an -

SU_ _ _ designation in the

part number, other technical

data may apply (affecting

calibration, wiring, dimen-

sions etc.).

Group 1, Class A

Noise immunity tests:

Static electricity (ESD)

EN 61000-4-2

Severity level 3

Electromagnetic fields (RFI)

EN 61000-4-3

Severity level 3

Fast transients (Burst)

EN 61000-4-4

Severity level 3

Surge

EN 61000-4-5

Severity level 2

Line-induced noise induced by

high-frequency fields

EN 61000-4-6

Severity level 3

Magnetic fields

EN 61000-4-8

Severity level 4

The CE Mark verifies that

our products meet the

requirements of

EC Directive

89/336/EEC (EMC Directive)

and the EMC Law. Testing in our

EMC Laboratory, which is accredited

by DATech for Testing Electromag-

netic Compatibility, has confirmed

that Balluff products meet the EMC

requirements of the following

Generic Standards:

EN 50081-2 (emission)

EN 61000-6-2 (noise immunity)

Emission tests:

RF Emission

EN 55011

The following patents

have been granted in

connection with this

product:

US Patent 5 923 164

Apparatus and Method for

Automatically Tuning the

Gain of an Amplifier

US Patent 5 903 426

Overvoltage Protection

Apparatus for Data

Interface

Summary of Contents for BTL5-P

Page 2: ......