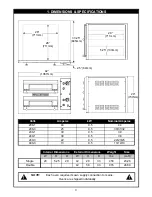

4

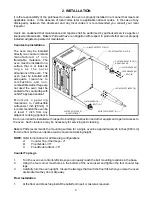

2. INSTALLATION

It is the responsibility of the purchaser to insure the oven is properly installed in a manner that meets all

applicable codes. In the absence of local codes refer to applicable national codes. In the case of any

discrepancy between this document and any local codes it is recommended you consult your local

inspector.

Users are cautioned that maintenance and repairs shall be performed by authorized service agents or

licensed professionals. Bakers Pride will have no obligation with respect to products that are not properly

installed, adjusted, operated or maintained.

LEG WITH FOOT INSERT (4)

LEG WITH CASTER PLATE (4)

CASTER WITHOUT LOCK (2)

MOUNT IN REAR

CASTER WITH LOCK (2)

MOUNT IN FRONT

BULLET FOOT INSERT (4)

4 inch COUNTER TOP LEG (4)

FLAT WASHER (16)

LOCK WASHER (16)

BOLT (16)

FLAT WASHER (12)

BOLT (12)

Counter-top Installation

The oven may be installed

directly on a counter or stand

m a n u f a c t u r e d

o f

n o n -

flammable materials. The

oven must be installed on a

surface that is at least as

l a r g e

a s

t h e

o u t e r

dimensions of the oven. The

oven must be installed with

adequate clearance t o

c o m b u s t i b l e

a n d

n o n -

combustible walls. If legs are

not used the oven must be

sealed to the countertop with

an NSF approved sealant.

M i n i m u m

o p e r a t i n g

clearances to combustible

surfaces is 1 inch [25 mm]. It

is recommended the oven be

at least 1 inch from any

adjacent cooking appliance.

Each oven shall be installed with respect to building construction and other equipment to permit access to

the oven. Such clearance may be necessary for servicing and cleaning.

Bakers Pride recommends the mounting surface for a single oven be approximately 26 inches [660 mm]

from the floor so the oven decks are at a convenient working height.

1.

Turn the oven over onto its left side so you can easily reach the bolt mounting locations in the base.

2.

Using the four corner most holes in the bottom of the oven insert and tighten the four counter top

legs.

3.

Carefully turn the oven upright. Insure the two legs that touch the floor first when you raise the oven

are blocked so they do not slip away.

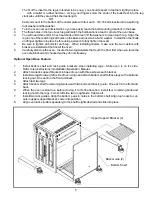

1.

At the floor end of each leg install the bullet foot insert or caster as required.

NOTE:

Counter Top Legs

Floor Installation

Refer to illustration for all three leg configurations.

A.

Counter Top - Short Legs - 4”

B.

Floor Model - 30”

C.

Floor/Double Stack - 16”