HEAVY DUTY HOT PLATE OPERATION MANUAL

6

LIGHTING INSTRUCTIONS

Main Burner Air Supply:

For efficient burner operation, a proper balance of gas

volume and primary air supply must be maintained

which will result in complete combustion. Insufficient air

supply results in a yellow streaming flame. Primary air

supply is controlled by an air shutter on the front of the

burner. Loosen the screws on the front of the burner,

and adjust the air shutter to just eliminate the yellow

tips of the burner flame. Lock the air shutter in place by

tightening the screws.

European Community:

If adjustment becomes necessary in the field, it should

be done by a factory authorized and trained technician

who should seal the screw after the adjustment to

safeguard against unauthorized tampering by the end

user.

All burners are lit from constantly burning pilots.

Turning the valve to the desired flame height is all that

is required to put the unit in service.

Do not permit fans to blow directly at the unit. Wherever

possible, avoid open windows next to the units’ sides

or back. Avoid wall type fans which create air cross-

currents within a room.

It is also necessary that sufficient air should be allowed

to enter the room to compensate for the amount of

air removed by any ventilating system. Otherwise, a

subnormal atmospheric pressure will occur, affecting

operation and causing undesirable working conditions.

A properly designed and installed hood will act as the

heart of the ventilating system for the room or area

in which the unit is installed, and will leave the unit

independent of changing draft conditions.

All valves must be checked and lubricated periodically.

This must be done by an authorized service

representative in your area.

MAINTENANCE

Use only non-abrasive cleaners. Abrasive cleaners

could scratch the finish of your unit, marring

its appearance and making it susceptible to

dirt accumulation. Do Not use steel wool, other

abrasive cleaners or cleaners/sanitizers containing

chlorine, iodine, ammonia, or bromine chemicals

as these will deteriorate the stainless steel and

glass material and shorten the life of the unit.

CAUTION

Daily:

1. Thoroughly clean back, sides, top and front of unit.

2. Clean grates daily.

Weekly

1. Clean unit thoroughly. Clean stainless steel or

chromed surfaces with a damp cloth and polish

with a soft, dry cloth. A detergent may be used for

cleaning. To remove discolorations, use a non-

abrasive cleaner.

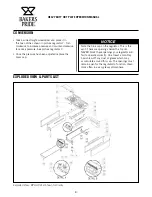

2. To clean the drip pan: Remove the drip pan by

grabbing the handle and pulling it out of the

opening in the front panel. To replace the pan,

reverse this procedure.

3. Burner air shutter openings must be kept clean.

4. Main burner ports must be kept clean. To clean

burners, boil them in a strong solution of lye water

for 15 to 20 minutes. Then either brush with a

wire brush or clean gas ports with a sharp pointed

metal instrument to insure open ports.

Clean the regulator at least once a month. Make

sure the vent opening is open and not blocked in

any way. Failure to do so will cause variations in

pressure. Your unit will not function as well and it

could shorten the life of the product.

CAUTION

Summary of Contents for BPHHP-212i

Page 13: ...11 NOTES...