Page

27

of

55

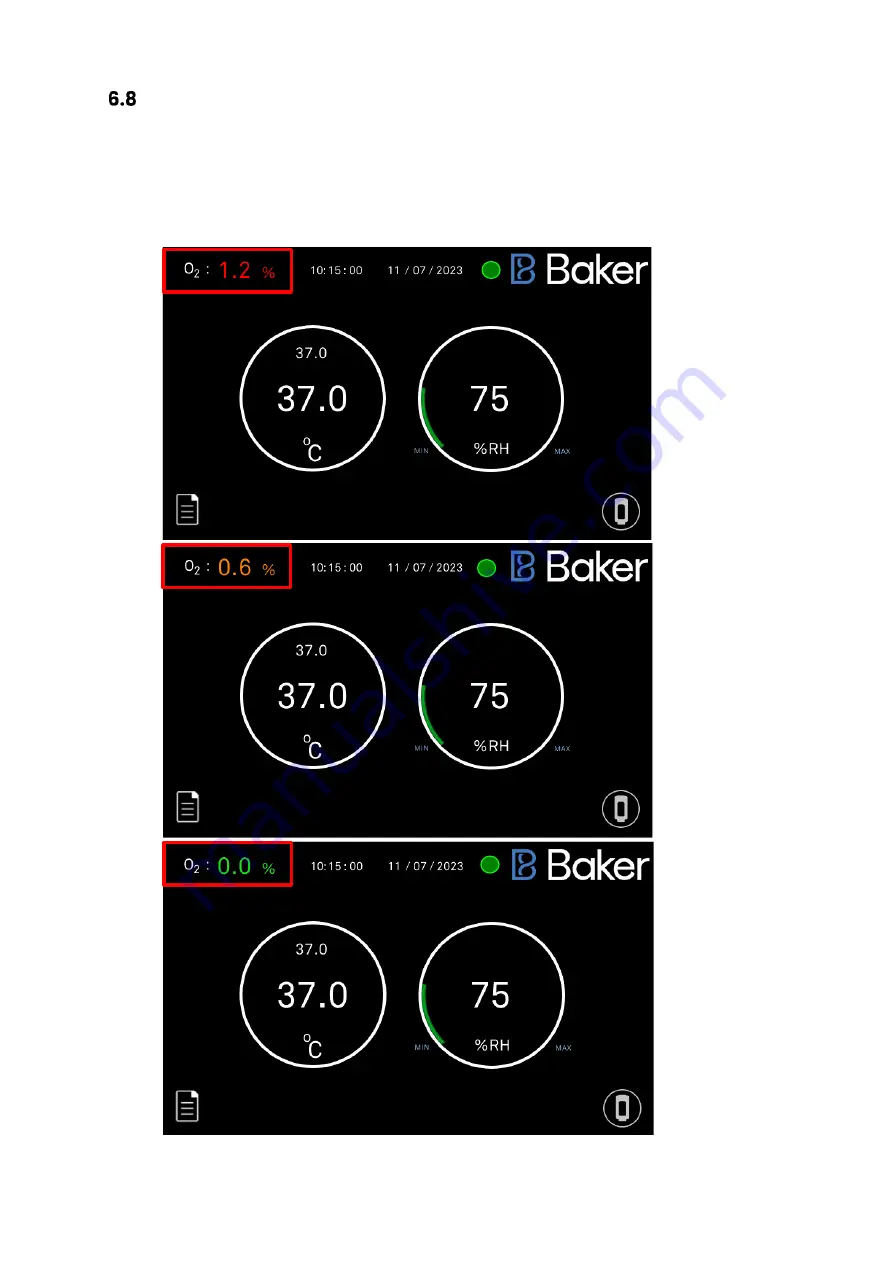

Anaerobic Monitoring (Optional Extra)

The Anaerobic Monitoring option displays the current level of Oxygen present within the

workstation. The O2 display can be seen in the top left of the screen. The O2 level text changes

colour based on the alarm set points that have been set. O2 alarm 2 is indicated by a red text. O2

alarm 1 is indicated by an amber text. Anaerobic conditions are displayed by a green text.