5 | Baker Hughes

Copyright 2020 Baker Hughes Company. All rights reserved.

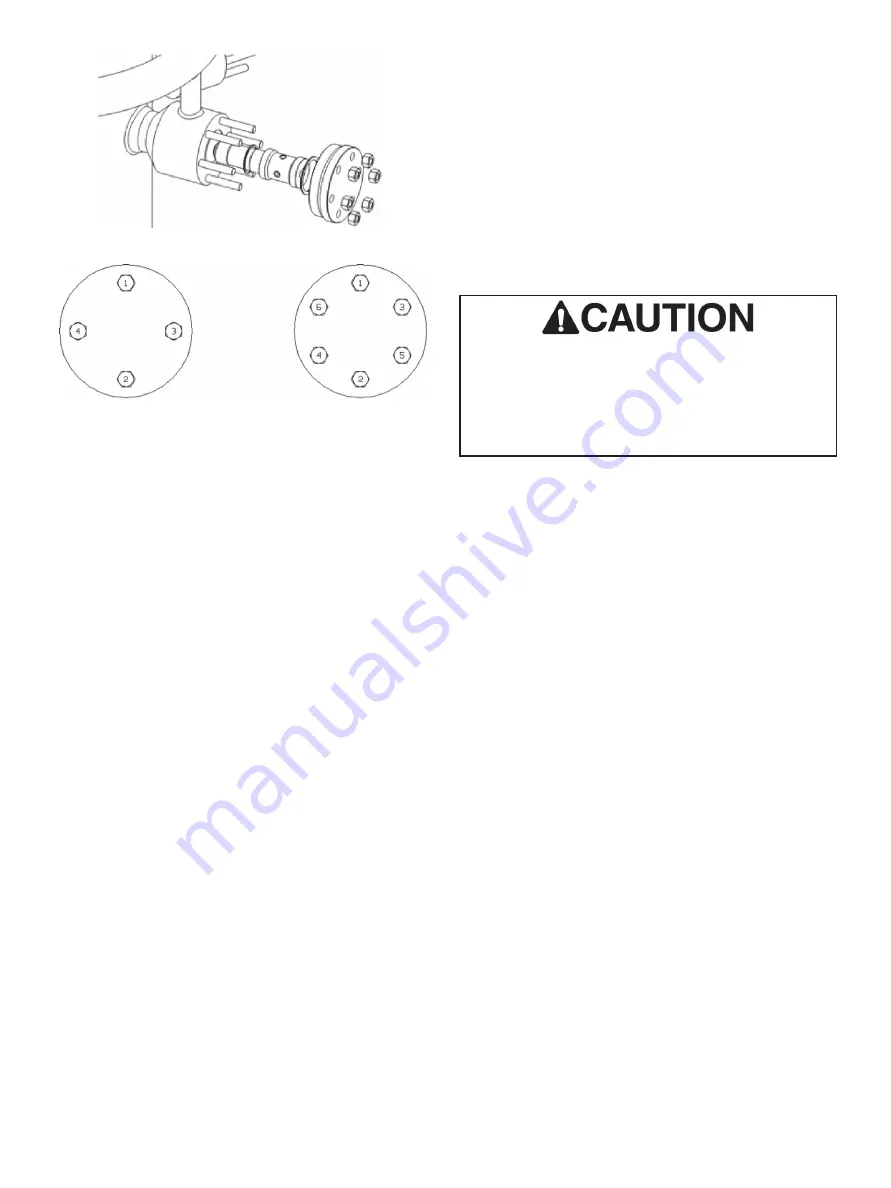

Figure 1 - Nozzle housing

Figure 2 - Bolt torquing sequences for nozzle flanges

Flushing Operations

Pipeline flushing is recommended to clean debris from the

pipeline resulting from its construction.

Water Ring Hydrostatic Testing

The hydro assembly drawing will specify whether the water ring

should require a separate hydrostatic test. DO NOT perform a

water ring hydrostatic test with the functional nozzles as expected

leakage and damage may occur to the functional nozzles. When

the blank nozzles are installed, ensure that both the inner and

outer gaskets are installed.

Downstream or Full Pipeline

Hydrostatic Testing

If the water ring is to be hydrostatically tested in conjunction with

the downstream pipe, it will be necessary at this point to remove

the blank nozzles, and reinstall the flange with a new outer

gasket and inner guide ring if required. It is important to note

that until hydrostatic testing has been fully completed; functional

spray nozzles must not be installed.

Nozzle Assembly

Desuperheating performance is reliant upon water injection of

the desuperheater spray nozzles. The nozzle must maintain

an aerosol spray effect, and a hollow cone spray pattern. Weld

slag, rust, and other debris in the water lines can disturb the

nozzle spray pattern and can result in poor water injection and

temperature control. Periodic inspection of the spray nozzle’s

water pattern should be conducted to ensure nozzle performance.

Refer to the instructions under “Inspecting Nozzle Performance”

for the detailed test procedure.

To assemble the nozzles into the desuperheater:

After inspecting the surfaces of the nozzle housing for any

damage or debris, install the nozzle gasket into the bottom of the

nozzle housing.

Securely install the nozzle holder into the nozzle housing. The

nozzle holder should fit flush with the housing surface, otherwise

remove the nozzle holder and confirm the nozzle is clean from

debris.

Install the nozzle flange gasket into the groove on the nozzle

housing.

Place the nozzle housing flange over the nozzle flange studs.

Securely tighten the nozzle flange nuts to the factory suggested

torque.

The nozzle assembly is screwed and locked in place

using a high temperature adhesive to prevent part

from coming loose due to thermal expansion caused

by the steam line. This assembly should not be

disassembled, and must be purchased as a complete

assembly.

Gaskets

Gasket seating surfaces must be free of dents, scratches,

and corrosion. Metal gasket glands should have a radial or

circular serration pattern with a surface roughness of 63 to

250 RMS. Clean mating surfaces as required and replace any

non-conforming parts. Spiral-wound gaskets must always be

replaced after disassembly.

Inspecting Nozzle Performance

Follow the disassembly instructions shown under the “Opening

Nozzle Housing” section.

1. With the nozzle holder removed from the nozzle housing,

plug the threaded holes in the side of the nozzle housing

using threaded plugs as listed in Table 2 (nozzle plug size).

2. Connect a water source to the threaded connection shown

in Table1 (lifting bolt size).

3. Apply pressure to the water line and observe the spray

pattern of the nozzle. The spray pattern should be uniform

and consistent around the perimeter of the nozzle head.

4. If nozzle spray pattern is disturbed, continue flushing

procedure with higher pressure water to determine if nozzle

can be unblocked.

5. If problem persists, contact the Baker Hughes Masoneilan

factory for a replacement nozzle assembly.

Note: The water pressure must be a minimum of 30 PSIG to

ensure the nozzle will overcome the spring coefficient and

spray properly.