20 |

Baker Hughes

© 2020 Baker Hughes Company. All rights reserved.

A. Metal Seat Valves (MS)

A1. Precautions and Hints for Lapping Seats

Reconditioning of the seat surface may be accomplished

by lapping with a flat cast iron ring lap coated with a 1000

grit lapping compound or its equivalent (see Table 17). A

cast iron lap, coated with a lapping compound, is used for

reconditioning the seating surfaces of the base (1) and disc

(2). The following will enable maintenance personnel to do a

“professional” job of lapping seats:

1. Keep work materials clean.

2. Always use a fresh lap. If signs of wearing (out

of flatness) are evident, recondition the lap.

Reconditioning of laps is accomplished by lapping them

on a flat lapping plate. The lapping should be done with

a figure-eight motion as indicated in Figure 9. To assure

the best results when lapping seats, the laps should be

reconditioned after each usage.

3. Apply a very thin layer of compound to the lap. This will

prevent rounding off the edges of the seat.

4. Keep the lap squarely on the flat surface and avoid any

tendency to rock the lap which causes rounding of the

seat.

5. When lapping, keep a firm grip on the part to prevent

the possibility of dropping it and damaging the seat.

6. Lap, using an eccentric, or figure-eight motion, in all

directions, while at the same time, applying uniform

pressure and rotating the lap slowly (see Figure 9).

7. Replace the compound frequently after wiping off the

old compound, and apply more pressure to speed the

cutting action of the compound.

8. To check the seating surfaces, remove all compounds

from both the seat and the lap. Then, shine the seat

with the same lap using the lapping motion described

above. Low sections on the seating surface will show up

as a shadow in contrast to the shiny portion. If shadows

are present, further lapping is necessary and only

laps known to be flat should now be used. Only a few

minutes will be required to remove the shadows.

9. When the lapping is completed, any lines appearing

as cross scratches can be removed by rotating the lap

(which has been wiped clean of compounds) on the

seat about its own axis.

10. The seat should now be thoroughly cleaned using a lint-

free cloth and a cleansing fluid.

A2. Lapping the Base Seat

For -1 Material Seat Design

The base seat may be reconditioned using the lapping

procedure; however, the dimensions provided in Table 2,

should be used to determine the seat width.

The seat width can be measured by the use of a “Measuring

Magnifier” (see Figure 10a). Baker Hughes recommends the

use of Model S1-34-35-37 (Bausch and Lomb Optical Co.)

or an equivalent. This is a seven power glass with a .750"

(19.05 mm) scale showing graduations of .005" (0.13 mm).

The use of this scale in measuring the seat width is shown in

Figure 10b.

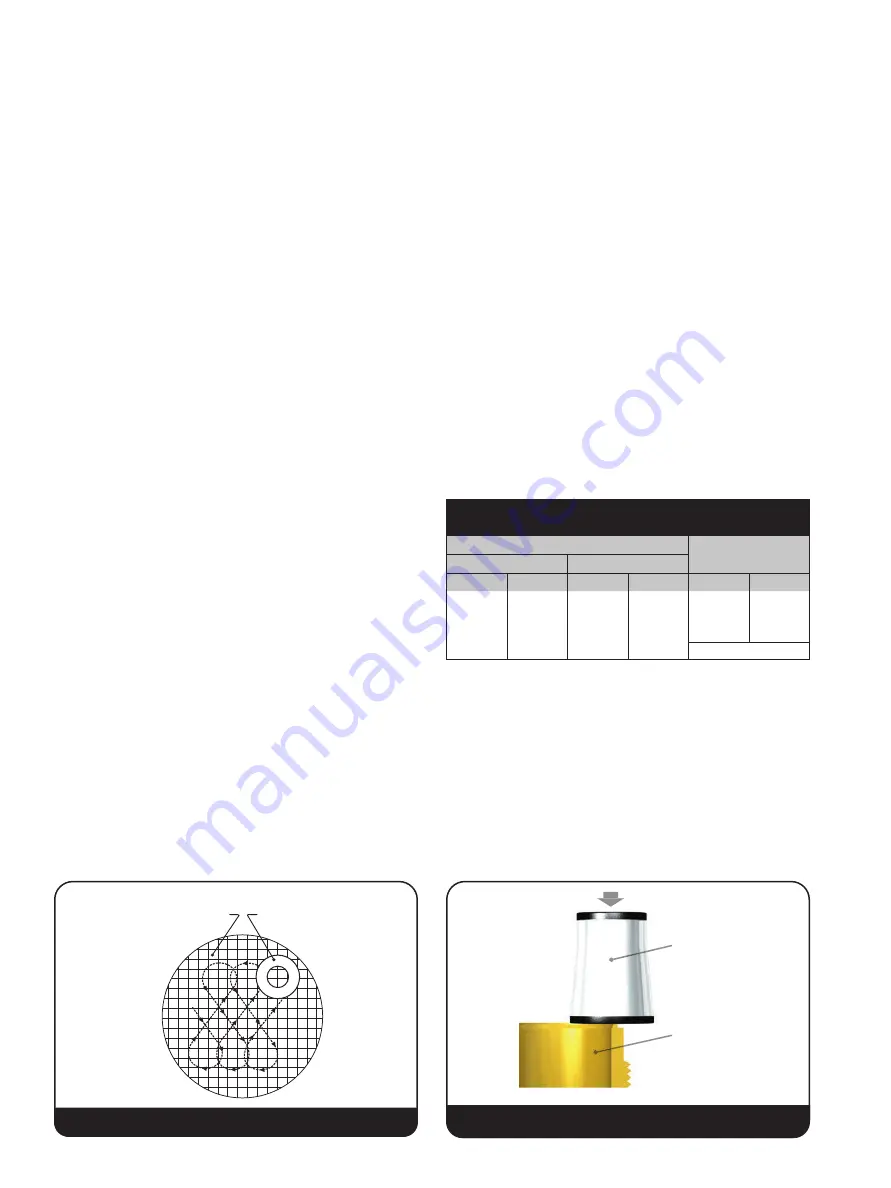

LAPPING PLATE

RING LAP

Figure 9: Lapping Pattern

Measuring

Magnifier

Base

Figure10a:MeasuringMagnifier

XIII. Maintenance

Table 2: Base Lapping Width

(-1 Metal Seat Design Only)

SET PRESSURE

SEAT WIDTH

psig

barg

min.

max.

min.

max.

in.

mm

5

100

0.34

6.89

.010

0.25

101

300

6.96

20.68

.015

0.38

301

800

20.75

55.16

.020

0.51

801

UP

55.23

UP

Note 1

1. Add .005” (0.127 mm) per 100 psig (6.896 barg), not to

exceed .070” (1.78 mm).

Summary of Contents for Consolidated 19000 DA

Page 2: ......