12

within 24 hours. If necessary, we will send technical personnel to the user site within 72 hours in the city, 3-5

days reaches the user site according to the distance outside the city until the problem is solved.

Complaints Tel: 022-26740033; Hotline: 022-26740033

(Note: The electric actuator should be stored in dry and non-corrosive circumstance.)

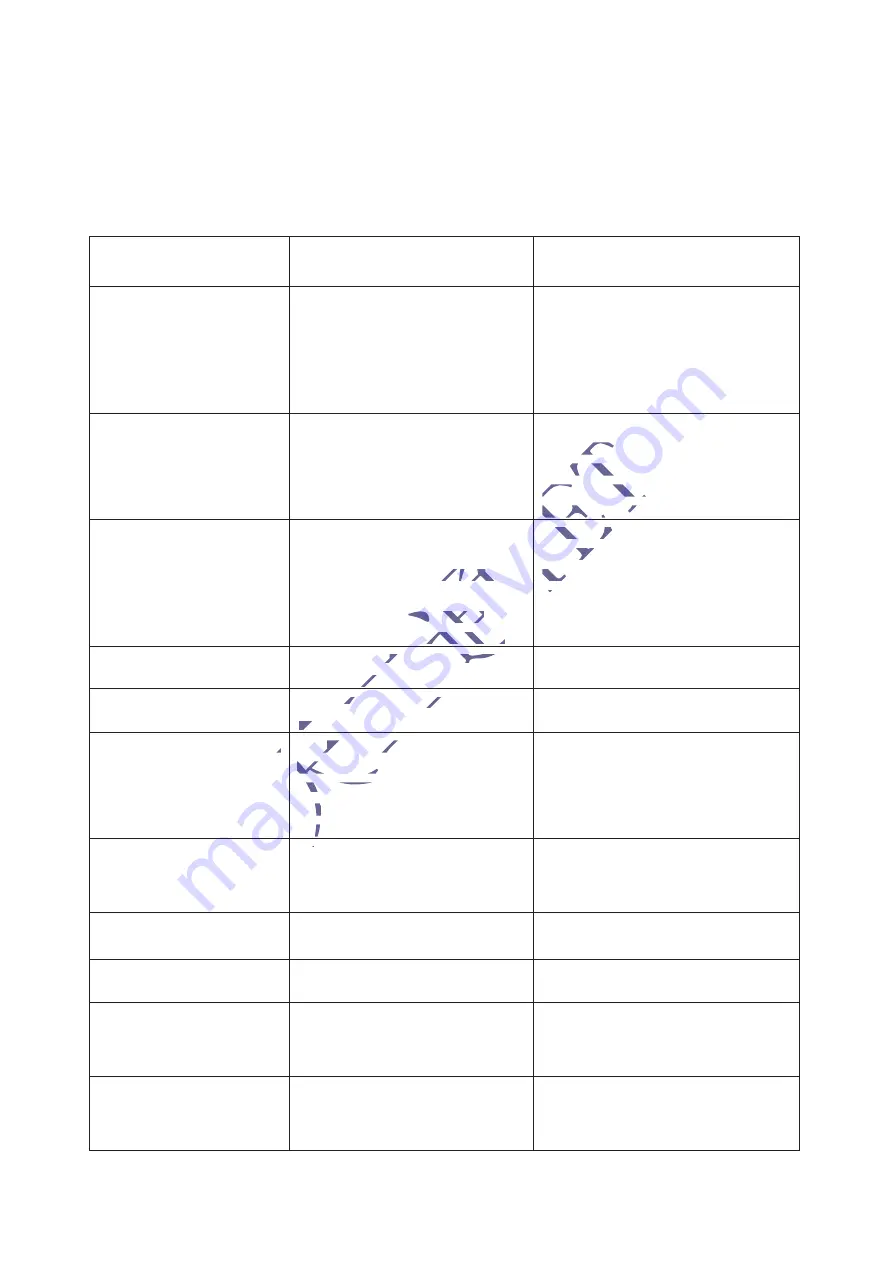

12.Trouble-shooting and remedy

Table 1

Trouble Cause

Remedy

1. Motor can’t started.

1. No power supply.

2. Too low power voltage.

3. Thermore lay (KH)acts.

4. T.SW acts.

5. Operation torque of valve is too high.

1. Inspect power supply.

2. Inspect voltage.

3. Wait for KH restoring to normal state.

4. Adjust T.SW to increase torque.

5. Forcibly starting.

6. Inspect valve.

2. Motor stops during open or

close operation.

1. T.SW act caused by overload.

2. Thermorelay acts.

3. Poor status of valve, excessive load.

1. In crease set value of torque if maximum

output torque allows.

2. Adjust thermorelay

3.1 Inspect valve and correct it into normal.

3.2 Operate the valve periodically if possible.

3.Motor can’t be stopped by

G.L.SW

1.The motor runs in reverse direction

2.Misadjustment of switch

3.Reset of screw is forgotten after

adjustment

4.Trouble on control power source

5. The gear of limit switch is damaged

1.Reverse the phase sequence

2.Readjust

3.Reset the adjusting screw

4.Inspect and remedy

5.Inspect and replace it with a new one if

necessary.

4. T.SW, G.L.SW acts, but the

motor can’t be stopped.

1.The motor runs in reverse direction

2.Trouble of grounding

1. Reverse the phase-sequence.

2. Inspect and measure resistance.

5. Indicating lamps for full open,

full close can’t be lighted up.

The T.SW acts, but the valve has not been

seated in position

Adjust T.SW

6.Remote position indication not

effective

1. The gear of signal output potentiometer

becomes loose so that the potentiometer

axle couldn’t be turned.

2. Improper power supply

3. The potentiometer is damaged.

1.Tighten the screw

2.Inspect the power supply

3.Replace it with a new one

7.The motor runs but valve is not

actuated

1. The Manual/Electric change over

mechanism is abnormal.

2.Locknut becomes loose

1. Dismantle, inspect and restore it to normal

operation.

2. Tighten and chisel the locknut

8. Manual operation can’t actuate

the valve.

The jaws of clutch and jaws of handwheel

body are out of meshing.

Turn the hand wheel a little to bring the jaws

into meshing.

9. Valve stem vibrates during

starting.

Stem nut becomes loose or improperly

tightened.

Dismantle the stem or pipe tap and tighten the

locknut.

10.Improper insulation

Invasion of rain water (improper sealing

of wire in wet)

1. Repair sealing parts.

2. Dry the electric elements and motor.

3. Pay attention to the sealing of wire inlet

11.Oil leakage

1. Sealing is damaged.

2.The ambient temperature is too high.

Internal pressure of main horsing rises up.

1.Inspect and repair

2.Loosen a screw which not affecting

working to vent air out (oil plug is preferred)

ཙҼ䙊7(7

rease

put torque a

torque

2. Adjust thermor

djust th

3.1 Inspect valve and c

3.1 Inspect valve an

3.2 Operate the valve

3.2 Operate the va

7(

tion

forgotten after

forgotten

rol power source

power source

f limit switch is damaged

tch is damaged

1.Reverse the pha

Reverse the

2.Readjust

djus

3.Reset th

3.Re

4.Insp

I

5

7(7

䙊7(

or runs in reverse direction

ns in reverse direction

uble of grounding

f gr

Ҽ䙊

he T.SW acts, but the valve h

W acts, but the valv

seated in position

sea

Ҽ

ཙ

not

ot

1. The gear of signal ou

he gear of sign

becomes loose so

becomes loose

axle couldn’t b

xle couldn’t b

2. Improper

Im

3. The p

Th

ཙҼ

ཙ

ཙ